Introduction

Packing and loading are where things often go wrong, a missed label, a weak seal, or a miscount can throw off the entire shipment. Relying only on manual checks slows things down and leaves room for mistakes. That’s why more businesses are turning to AI-powered inspection automation to speed up the process, cut errors, and keep quality consistent.

Sorting & Categorizing Packages

AI-powered classification ensures accurate sorting and packaging quality control.

Steps:

- Image Capture – High-speed cameras scan each package as it moves on the conveyor belt.

- Feature Extraction – AI models analyze size, shape, color, and texture to distinguish package types.

- Label/Barcode Recognition – Computer vision combined with OCR verifies SKUs, barcodes, or QR codes.

- AI-Based Classification – Packages are categorized into predefined classes (e.g., carton, pouch, bottle, fragile).

- Data Sync – Classification results are fed into the warehouse or logistics system for routing and tracking.

Steps:

- Conveyor Integration – Once classified, packages are assigned to the correct lane or chute automatically.

- Robotic Arms or Diverters – AI signals machines to physically sort packages into designated bins or pallets.

- Error Detection – If a package doesn’t match its expected category, the system flags it for manual review.

- Dynamic Adjustment – AI continuously learns from new data to improve sorting accuracy and adapt to packaging variations.

- Performance Monitoring – Dashboards track throughput, accuracy, and error rates for optimization.

Counting Packages in Real Time

Automated vision systems count packages instantly for inventory accuracy.

Steps:

- High-Speed Imaging – Cameras capture continuous video of packages moving across conveyors or pallets.

- Object Detection – AI models (e.g., YOLO, Faster R-CNN) identify each package, even when stacked or overlapping.

- Unique Tracking – Computer vision assigns IDs to packages to avoid double-counting.

- Counting Algorithm – The system tallies items frame by frame in real time.

- Accuracy Validation – AI cross-checks counts against expected order or shipment data.

Steps:

- System Integration – Count data is sent directly to ERP, WMS, or inventory systems.

- Error Detection – AI flags missing, extra, or miscounted packages instantly.

- Real-Time Alerts – Supervisors receive notifications when discrepancies occur.

- Adaptive Learning – Models improve with new data, handling variations like lighting or package shape.

- Analytics & Dashboards – Managers can view throughput, error rates, and efficiency in real time.

Verifying Labels & Barcodes

Computer vision inspects labels and barcodes for compliance and error-free delivery.

Steps:

- Image Capture – Cameras scan each package to detect label presence and orientation.

- Placement Verification – AI ensures labels are correctly aligned and not skewed or misplaced.

- Print Quality Inspection – Computer vision checks for faded text, smudges, or missing elements.

- Regulatory Validation – AI confirms required information like batch numbers, expiry dates, and safety warnings.

- Error Flagging – Packages with incorrect or missing labels are flagged for immediate correction.

Steps:

- Code Detection – Computer vision isolates barcodes or QR codes on each package.

- OCR & Decoding – AI deciphers printed data for accuracy and readability.

- Database Cross-Check – Scanned codes are matched against ERP/WMS records to ensure product identity.

- Readability Testing – AI simulates real-world scanning conditions (angles, poor lighting) to verify usability.

- Instant Alerts & Reports – Faulty or unreadable codes trigger real-time alerts, while clean data is logged automatically.

Ready to upgrade your packaging process?

Ensuring Seal Integrity

Automated vision detects weak or broken seals to ensure safe packaging.

Steps:

- High-Resolution Imaging – Cameras capture close-up images of package seals on the production line.

- Seal Zone Analysis – AI models focus on seal areas to check alignment, continuity, and closure strength.

- Defect Identification – Computer vision detects gaps, tears, incomplete seals, or broken closures.

- Tamper Detection – AI flags unusual patterns indicating tampering or resealing.

- Immediate Rejection – Faulty packages are diverted automatically for rework or disposal.

Steps:

- Pattern Matching – AI compares seal patterns against a “golden reference” of acceptable seals.

- Surface Inspection – Computer vision detects contamination like dust, oil, or product residue on seal lines.

- Consistency Check – AI ensures uniform seal pressure and bonding across all packages.

- Compliance Validation – Seal quality is checked against food safety, pharma, or industry standards.

- Data Logging & Reporting – All seal inspection results are recorded for traceability and quality audits.

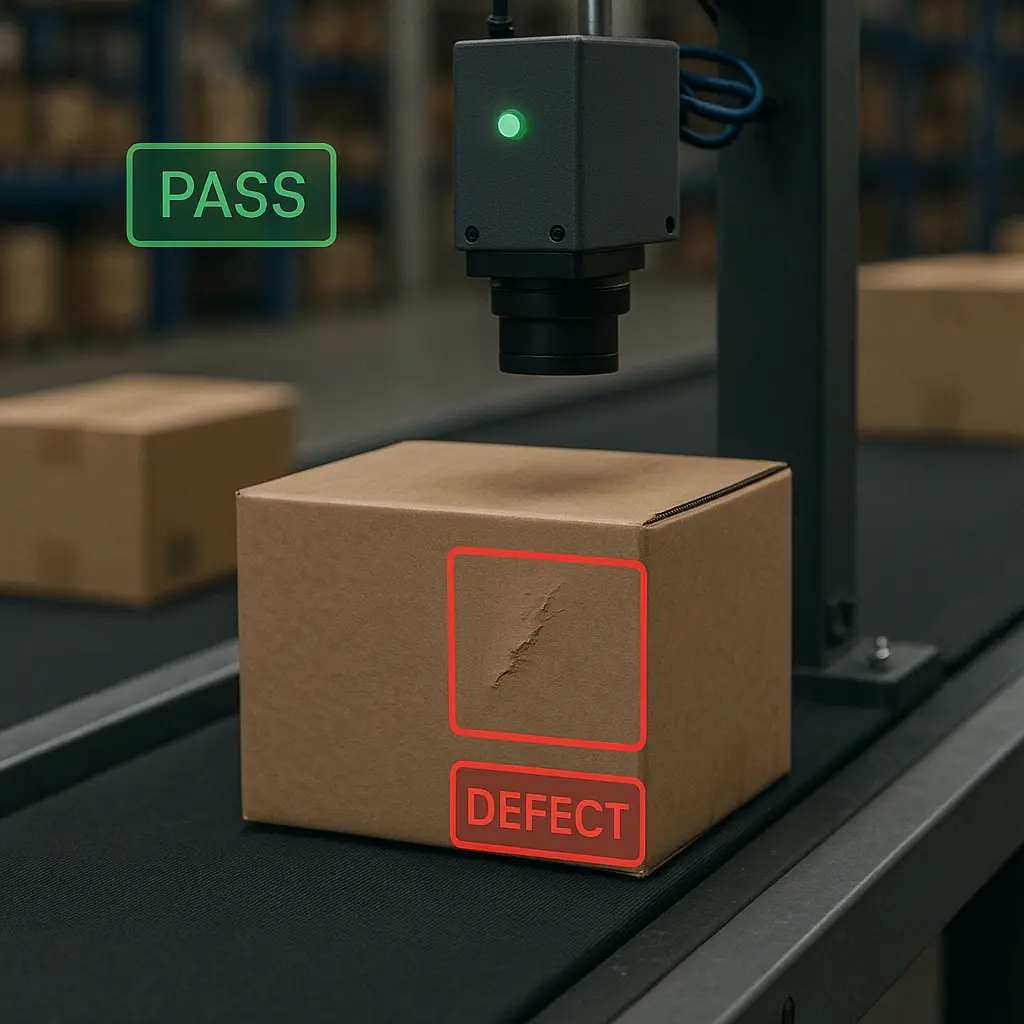

Detecting Packaging Defects

Deep learning identifies scratches, dents, and misprints before shipping.

Steps:

- Image Capture – High-resolution cameras scan package surfaces on all sides.

- Pattern Recognition – AI models detect irregularities like scratches, dents, or cracks.

- Print Quality Check – Computer vision compares fonts, colors, and graphics against the reference design.

- Anomaly Detection – Deep learning highlights differences that deviate from the trained “perfect” package.

- Real-Time Sorting – Defective packages are flagged and automatically removed from the production line.

Steps:

- 3D Shape Analysis – AI checks for deformities like crushed corners, warped edges, or improper folds.

- Logo & Branding Verification – Computer vision validates logos, brand colors, and layout accuracy.

- Seal Area Inspection – AI ensures no leaks, tears, or gaps that compromise product safety.

- Foreign Object Detection – Systems identify dirt, residue, or unwanted particles inside transparent packaging.

- Compliance Logging – Results are stored in dashboards for audits, quality assurance, and process improvement.

Checking Thermal Seals

Automated thermal seal inspection verifies heat-sealed packages for quality assurance.

Steps:

- Thermal Image Capture – Infrared cameras scan sealed areas immediately after the heat-sealing process.

- Temperature Mapping – AI analyzes heat distribution across the seal zone to identify inconsistencies.

- Defect Identification – Weak, overheated, or uneven seals are detected in real time.

- Contamination Check – Vision systems spot particles or product residue trapped inside the seal line.

- Instant Flagging – Packages with defective seals are automatically diverted for rework or rejection.

Steps:

- Seal Strength Verification – AI ensures consistent bonding across the entire seal length.

- Comparative Analysis – Seal patterns are matched against a “golden reference” of acceptable seals.

- Predictive Quality Control – Continuous data analysis predicts machine faults before they cause seal failures.

- Regulatory Compliance Check – Packaging is validated against food, pharma, and safety standards.

- Data Logging & Reporting – Every seal inspection is recorded for traceability, audits, and quality assurance.