Introduction

Simply reacting to breakdowns or bottlenecks in now-existing hyper-competitive industrial and urban environments, isn’t good enough. The next leap is prediction and optimisation, anticipating failures, simulating scenarios, and steering systems proactively. At the heart of this transformation sits the convergence of two powerful concepts: the digital twin and artificial intelligence (AI).

In this article I’ll walk you through how digital twins plus AI are enabling simulation-driven environments across factories, ports and cities, what this means, how it works, what benefits we see, what challenges remain, and how you can think about adopting it.

What is a Digital Twin?

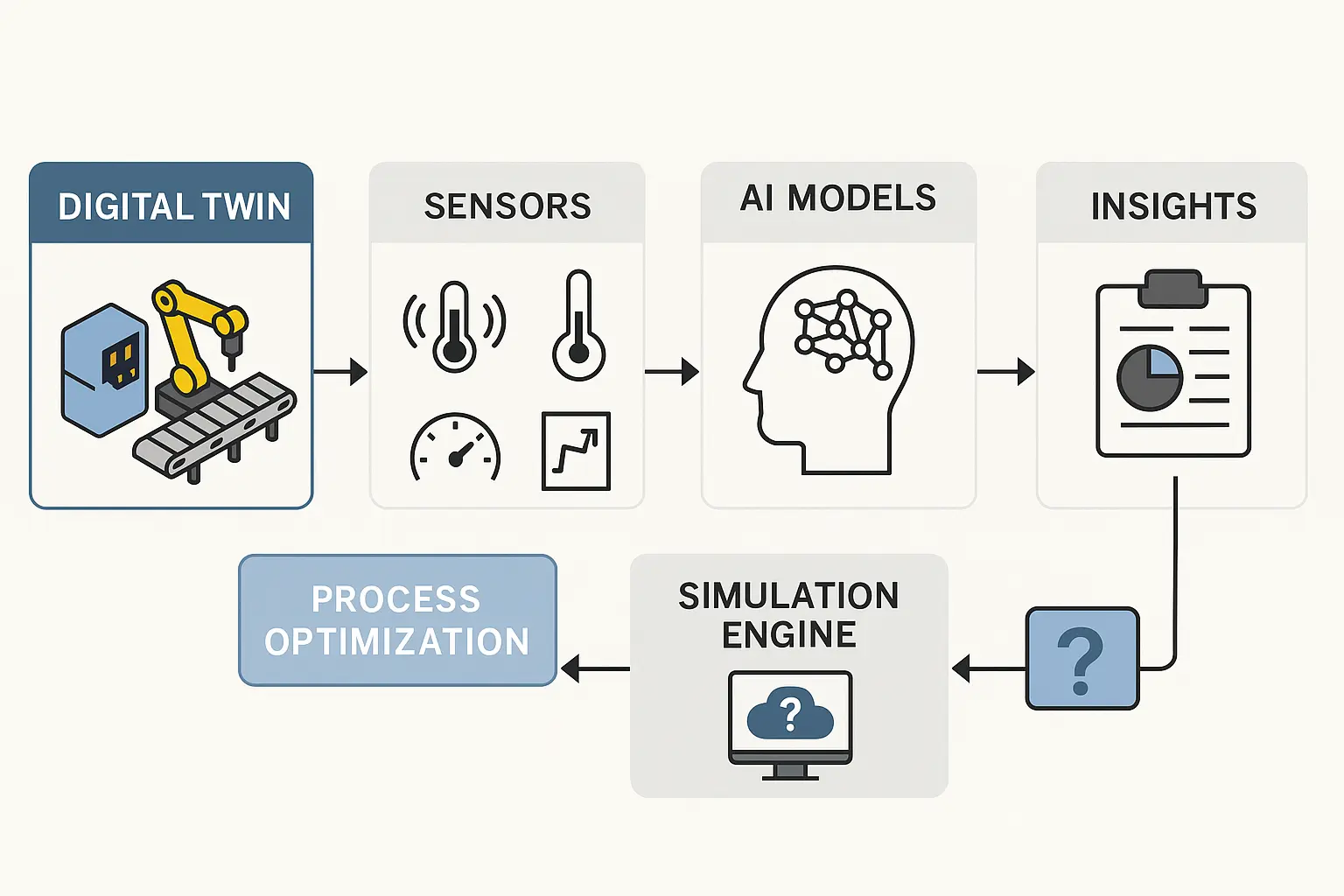

A digital twin is more than just a static model of something physical. It is a live virtual replica of a physical asset, process or system continuously fed by real-world data, capable of simulation, monitoring, prediction, and even influencing the real system.

Here are some key attributes:

- A digital twin mirrors the physical system in geometry, behaviour, and context.

- It receives sensor / IoT data streams (temperature, vibration, flow, utilisation, etc) to stay in sync.

- It is not purely monitoring, it can run what-if simulations, evaluate alternative scenarios, and feed optimisation outcomes back into the system.

- When paired with AI/ML models, the twin goes beyond “look what’s happening” to “here’s what will happen” and “here’s what we should do”.

Thus, when I say “digital twin + AI”, I mean a simulation-driven twin: one that uses AI to analyse, predict and optimise, not just mirror.

Get to know how Siemens' Digital Twin + AI Transformed Schneider Electric's Manufacturing Efficiency

A great real‑life example of Digital Twin + AI in action is Siemens and their Smart Manufacturing solution for Schneider Electric’s factory in France.

Schneider Electric, a global leader in energy management and automation, partnered with Siemens to implement digital twin technology in their factory operations. The goal was to enhance energy efficiency, predictive maintenance, and optimise overall factory productivity.

Siemens created a digital twin of Schneider Electric’s factory, integrating sensors to track real-time data from machinery and systems. AI algorithms processed this data for predictive maintenance, anticipating machine failures before they occurred. The digital twin also ran what-if simulations to optimise production, adjusting processes without disrupting operations.

Outcome:

Predictive maintenance reduced downtime and costs by addressing failures before they happened. Energy consumption was optimised, leading to cost savings and environmental benefits. Operational efficiency improved by 15% through better decision-making and scenario planning.

How Digital Twins + AI Create Simulation Environments

Let’s unpack the mechanics of how digital twins and AI combine to create simulation‑environments for factories, ports and cities.

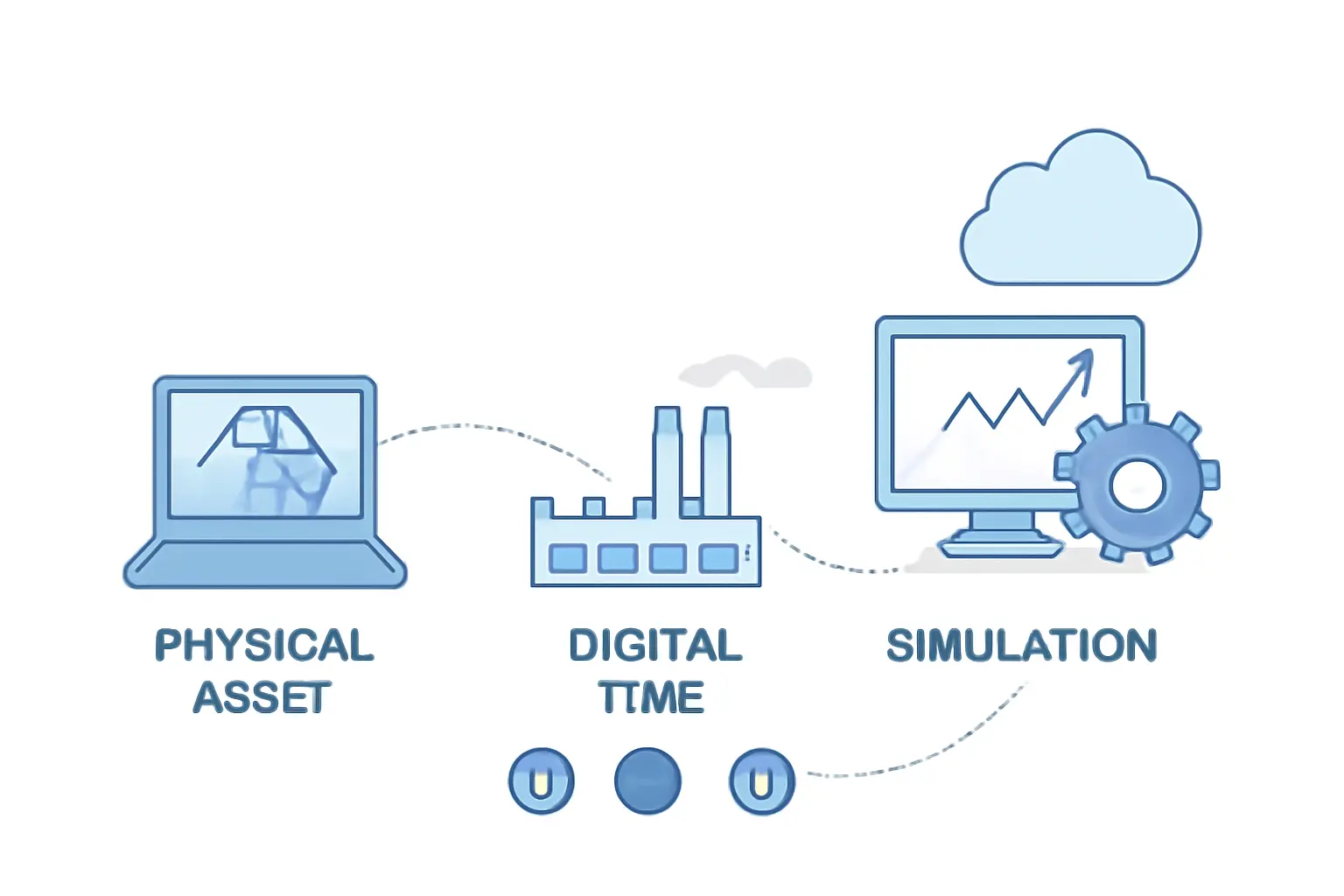

The building blocks

To build a simulation environment you need:

Physical asset / process / system

e.g., a production line, a port terminal, or a city traffic network.

Sensors & IoT

devices capturing real‑time or near‑real‑time data (vibration, temperature, flow, occupancy, etc.).

Data infrastructure

pipelines, storage (edge/cloud), streaming platforms, data lakes.

Virtual model / twin

geometry + behaviour + context (the digital representation).

Simulation engine

modelling of behaviour, what‑if scenarios, plus behavioural dynamics.

AI/ML layer

analysing historical data, learning patterns, forecasting degradation or bottlenecks, optimising decisions.

Feedback loop / control

twin suggests or triggers actions in the real system (maintenance alerts, process tweaks).

Visualisation & decision interface

dashboards, 3D models, operator/user engagement with insights.

Ready to bring predictive intelligence into your operations?

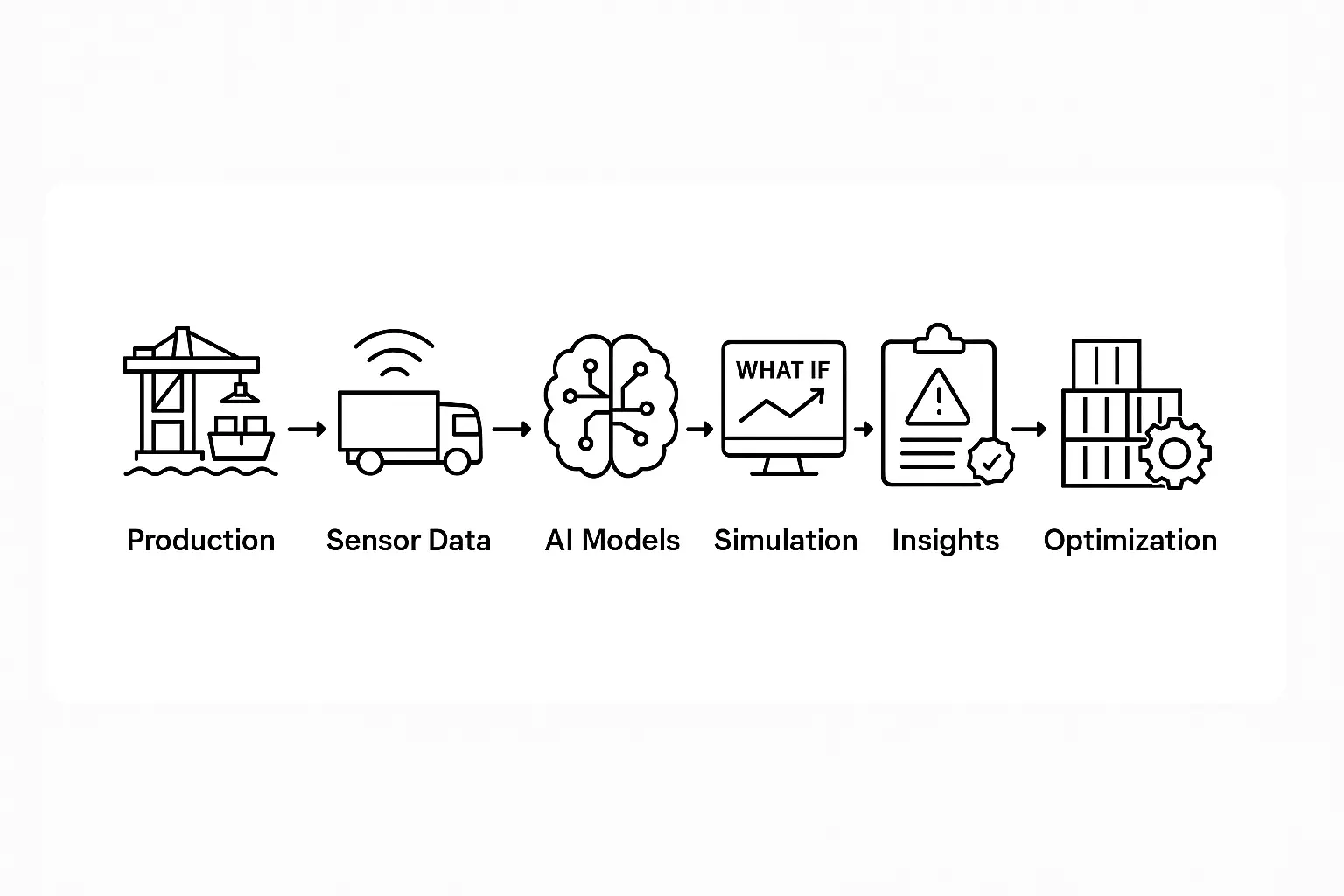

Application Domain I: Factories / Manufacturing Workflow

A digital twin of a production line is created by integrating 3D/2D models and real-time data from machines, conveyors, robotics, and sensors. Sensors monitor variables like vibration, temperature, speed, and throughput, while AI models analyze historical data to detect anomaly patterns and predict machine failure risks. The simulation engine runs “what-if” scenarios, such as adjusting conveyor speed or postponing maintenance, to assess potential impacts.

For example, insights might reveal a 75% chance of failure in a robot arm within 30 days, prompting proactive maintenance. Additionally, simulations help optimize throughput, reduce energy consumption, minimize waste, and balance workload across the production line.

Benefits & Evidence

For predictive maintenance

Digital Twins integrate advanced sensors, real‑time data processing, and AI models to simulate, analyse, and optimise asset performance.

Academic review

In the maintenance domain, digital twins provide via AI algorithms, increasing accuracy and depth of insight.

Review

The review of smart manufacturing shows digital twin technology can enhance efficiency and reduce costs.

Start with high-value assets, where downtime is costly, and ensure data quality to avoid misleading predictions. Integrating with maintenance systems like CMMS and ERP is essential, while human technicians must interpret and act on insights. Finally, scalability requires a strong architecture and governance to extend the digital twin across the entire factory.

Application Domain II: Ports & Logistics Hubs

Ports are complex systems involving moving assets, cranes, containers, ships, yard operations, traffic flows, supply chains.

A digital twin of the port environment is created, capturing real-time data on quays, cranes, container stacks, trucks, gates, and ships. Sensors monitor crane movements, container weight, yard occupancy, truck queues, and ship arrivals, while AI models forecast bottlenecks, container dwell times, and equipment failures. Simulations explore scenarios like crane breakdowns, alternative yard layouts, or vessel delays. The insights enable proactive maintenance of critical equipment, optimisation of yard flows, minimisation of waiting times, and better resource allocation.

Practical Benefits

Reduced crane idle time and breakdowns via proactive maintenance.

Improved container throughput by optimising yard layout and flows.

Lower dwell times for trucks by predicting gate congestion and scheduling accordingly.

Enhanced resilience to disruptions (weather, ship delays) because simulation allows “what‑if” planning.

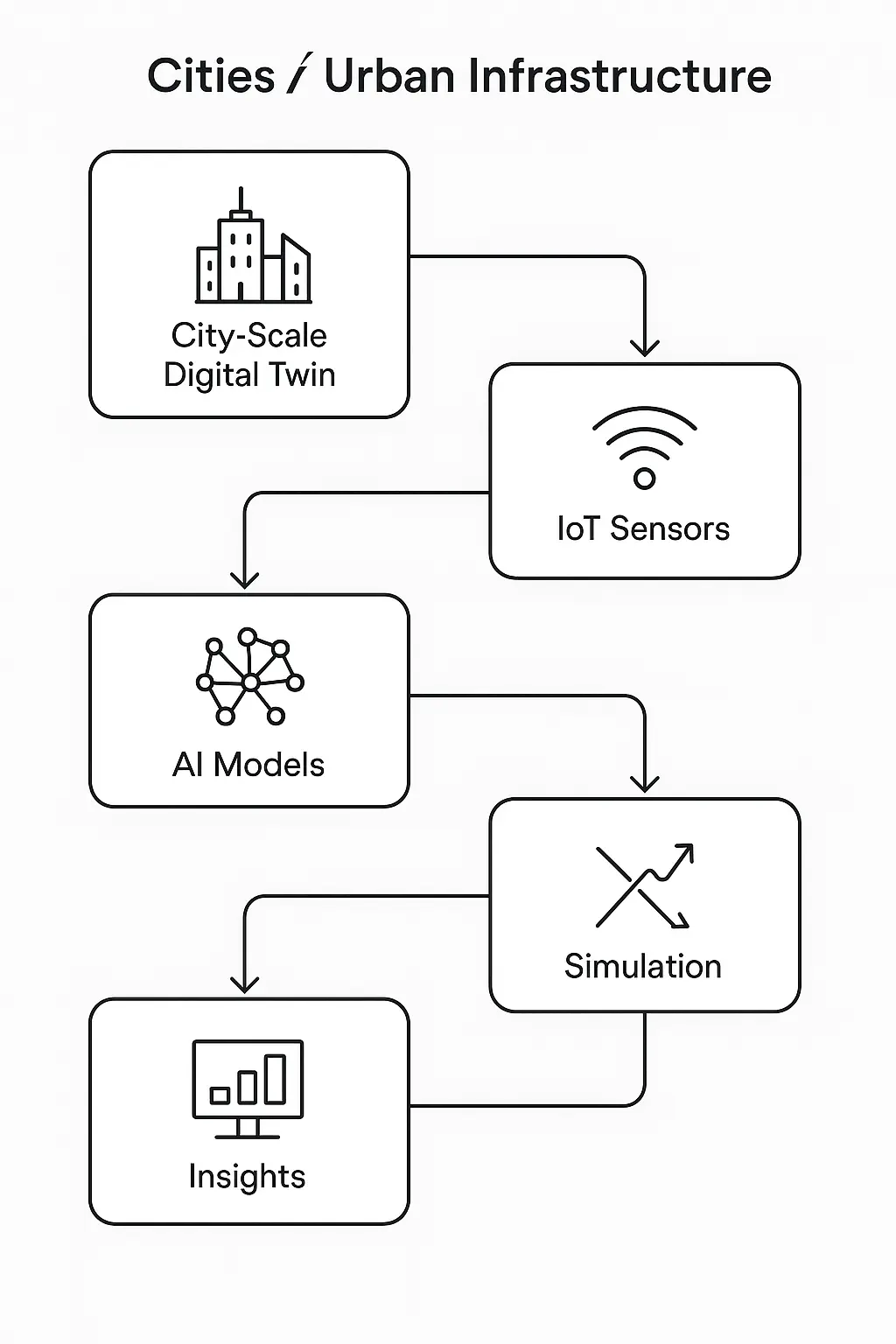

Application Domain III: Cities & Urban Infrastructure

Cities represent one of the most ambitious areas for simulation-driven AI and digital twins. By building a city-scale digital twin encompassing buildings, roads, utilities, traffic flows, and public services, along with IoT sensors for real-time data (e.g., traffic cameras, air quality monitors, public transport GPS), AI models can forecast congestion, energy demand, building performance, and infrastructure maintenance needs.

Simulations allow for testing scenarios such as the effects of new transit lines, extreme weather events, or power outages. Urban decision-makers can use these insights to optimise resource allocation, improve sustainability, and proactively maintain infrastructure, while engaging citizens through visualisation tools.

Practical Benefits and Challenges of Digital Twins in Smart Cities

Transforming maintenance from reactive to proactive.

Traffic management is improved through simulation of flow and congestion prediction, while energy efficiency is optimised by simulating building and district energy profiles.

Emergency planning is enhanced through evacuation and disaster scenario simulations.

However, challenges include managing massive data volumes, ensuring real-time synchronization between the physical and digital, coordinating across various departments, and addressing privacy and security concerns. Large-scale city twins also pose difficulties in ROI calculation and investment, requiring careful planning and integration across public and private sectors.

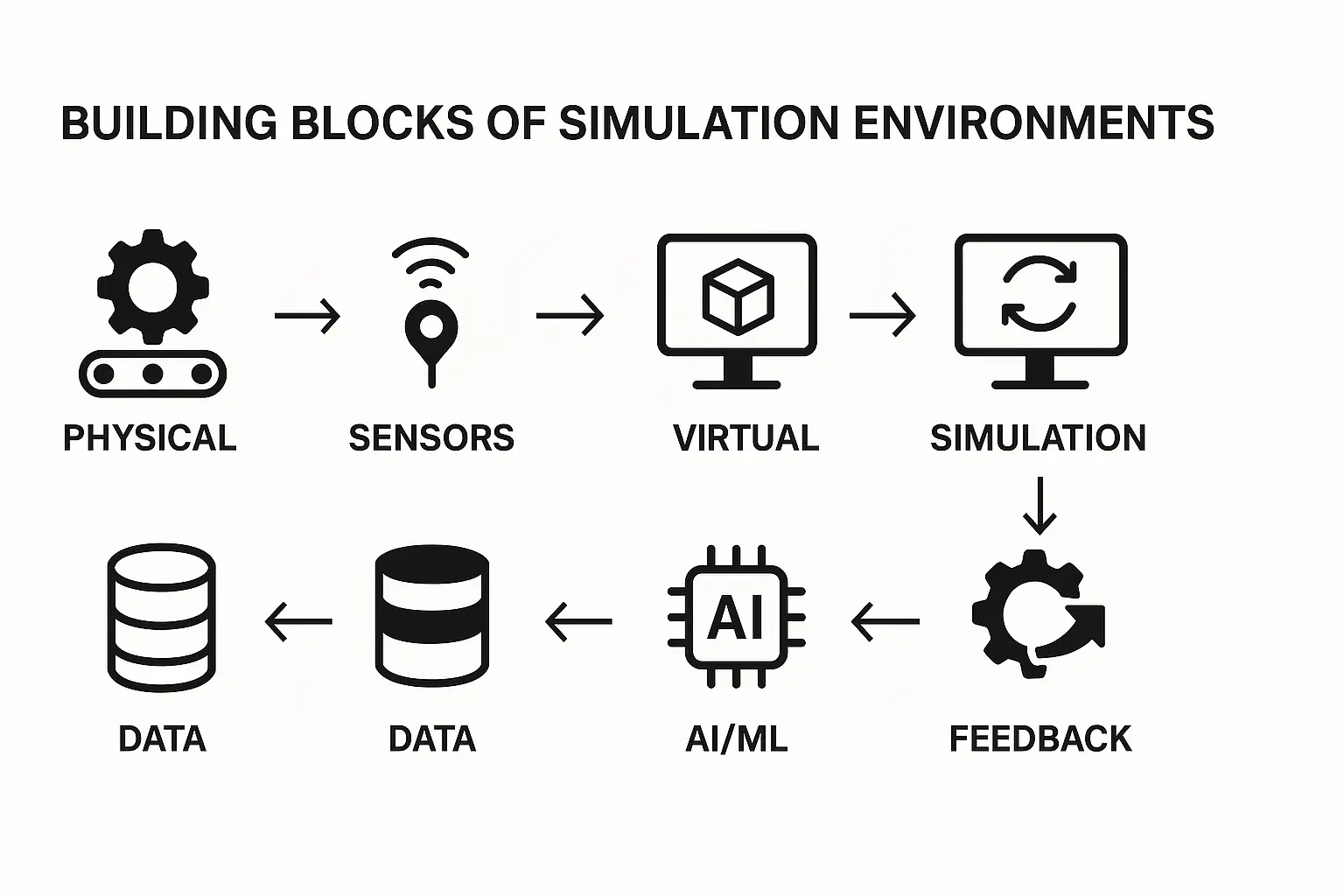

End‑to‑End Workflow: From Data to Action

To illustrate how everything fits together, here is a simplified end‑to‑end workflow:

Asset Instrumentation & Data Gathering

Physical assets (machines, cranes, roads, sensors) are instrumented. Sensors stream data (vibration, temperature, motion, flow, location, etc).

Data Ingestion & Cleansing

The raw data is ingested into a data platform (edge/ cloud), cleaned, aggregated, contextualised (which machine, which line, which truck, which road segment, etc).

Digital Twin Modelling

A virtual model is built: geometry, behaviour, relationships, and connection to the data. It could be a factory line, a port yard, or a city district.

AI Analytics & Simulation

AI models analyse historical + real‑time data to forecast key metrics (failures, throughput, traffic congestion, energy usage). The simulation engine allows “what‑if” scenario analysis.

Decision Support

The twin presents visualisations, dashboards, alerts and recommended actions (“schedule maintenance”, “reconfigure yard”, “reroute traffic”).

Execution & Feedback Loop

Actions are executed in the physical system (maintenance performed, process changed, traffic signal adjusted). The results feed back into the twin, refining its models (machine learning loop).

Continuous Optimisation

The twin continues to learn from new data, update its simulations, and improve predictions and recommendations over time.

Challenges & Pitfalls

Even with all the promise, there are obstacles to bear in mind:

Complexity & cost

Building a high‑fidelity twin across many assets is resource‑intensive.

Data silos

Legacy systems may not integrate well; sensor retrofit may be required.

Latency & real‑time demands

Especially in logistics/ports/cities, the twin needs timely updates; lag degrades accuracy.

Model drift & maintenance

As the physical system changes, the twin must be updated or predictions will go wrong.

Organisational resistance

Operations teams may fear change or not trust the twin’s output; cultural adoption is important.

Scalability

A pilot may work; scaling to hundreds of assets or a full city adds complexity.

Privacy and compliance

In cities especially, citizen data may be involved—privacy regulations must be adhered to.

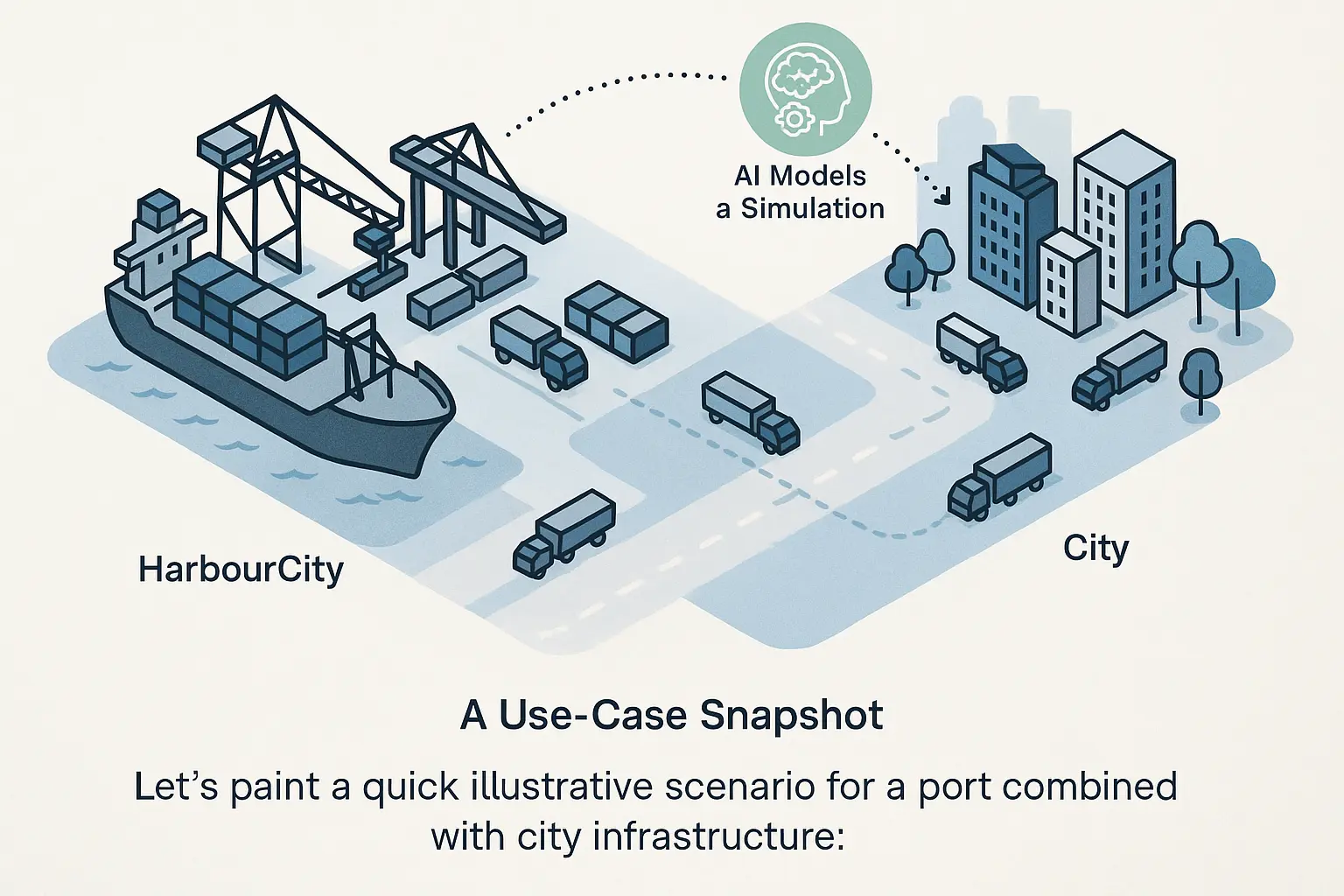

A Use‑Case Snapshot

Let’s paint a quick illustrative scenario for a port combined with city infrastructure:

Imagine the port of “HarbourCity”. They build a digital twin of the port yard, container cranes, trucks, gate operations. Simultaneously the adjacent city’s freight traffic and trucks heading to the port are modelled in a city twin. AI models forecast crane failures, yard congestion, truck queue delays and city‑road bottlenecks. They simulate scenarios when a vessel arrives late, gates are understaffed and trucks are queued.

The twin recommends adjusting crane schedules, rerouting trucks on alternate roads, and scheduling maintenance on a crane showing early vibration anomaly. Over time the twin learns that a specific type of container stack layout leads to longer dwell times and recommends a new yard configuration which is simulated and later deployed. The result is, lower truck wait time, higher throughput, fewer crane breakdowns, less traffic congestion in the city, and reduced CO₂ emissions from idling trucks.

Conclusion and what we are moving forward to

Looking to the future, several trends are emerging in simulation-driven AI and digital twins. One trend is greater autonomy in digital twins, where they could learn on their own, identify opportunities, and suggest product improvements entirely autonomously. Another development is the rise of semantic and cognitive digital twins, which will incorporate richer data context and cognitive capabilities.

Additionally, generative AI may enhance digital twins by proposing novel configurations or designs beyond simple predictions. The integration of factory, port, and city twins into broader ecosystems and supply chains is another exciting area, enabling more comprehensive optimisation. As sustainability becomes a key focus, digital twins will increasingly model environmental impacts, energy consumption, and carbon emissions.

Finally, cloud-based digital twin platforms will democratise access to this technology, allowing even smaller operations to leverage its benefits.