AI-Driven SCADA System Monitoring

SCADA

The world’s largest floating desalination plant required an advanced solution to enhance operational efficiency, ensure proactive maintenance, and improve system reliability. Traditional SCADA systems lacked real-time monitoring and proactive maintenance capabilities, often leading to unexpected downtimes and increased operational costs.

TECH STACK

CLIENT

SCADA

SERVICE PROVIDED

Application Design, Application Development

YEAR

2024

An AI-driven monitoring system was implemented to provide real-time insights, secure data handling, and comprehensive analytics without direct network access.

The Problem

- 1. Traditional SCADA systems lacked comprehensive real-time monitoring, leading to delayed responses to operational anomalies.

- 2. Maintenance was often reactive due to the absence of real-time insights, resulting in unexpected downtimes and higher operational costs.

- 3. Direct network integration of monitoring tools posed significant security risks.

- 4. Managing and interpreting vast amounts of SCADA data manually was time-consuming and prone to errors.

Key Requirements

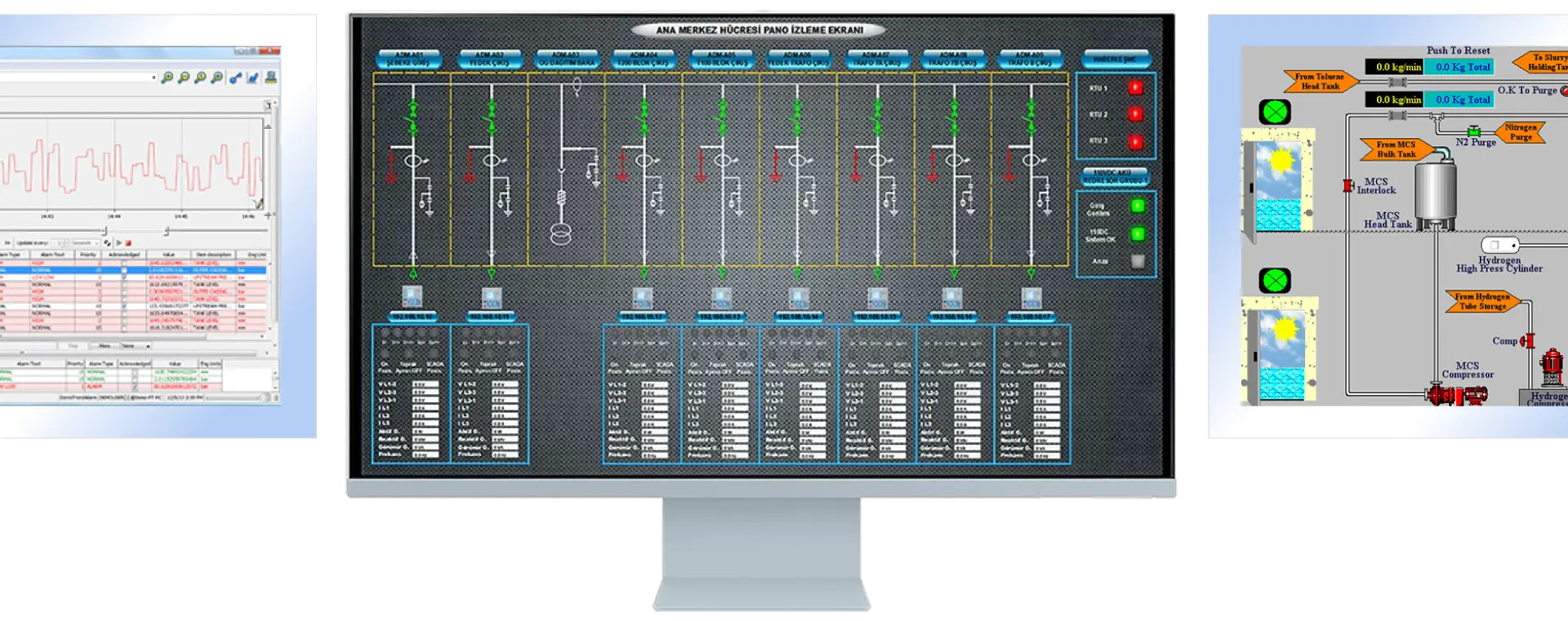

1. Real-time monitoring of SCADA activities without direct network access.

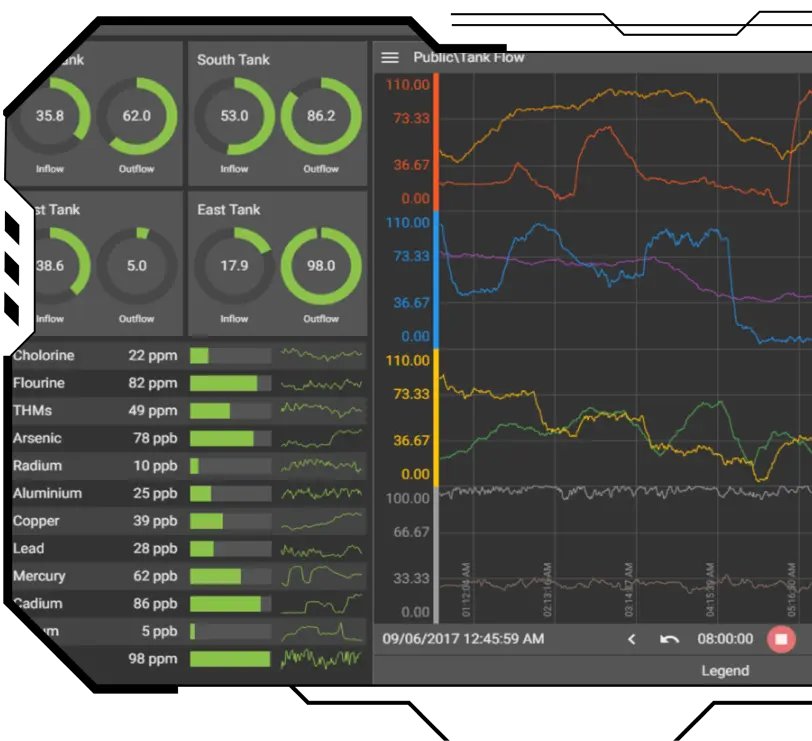

2. Comprehensive analytics dashboard for operational insights.

3. Secure data handling and storage.

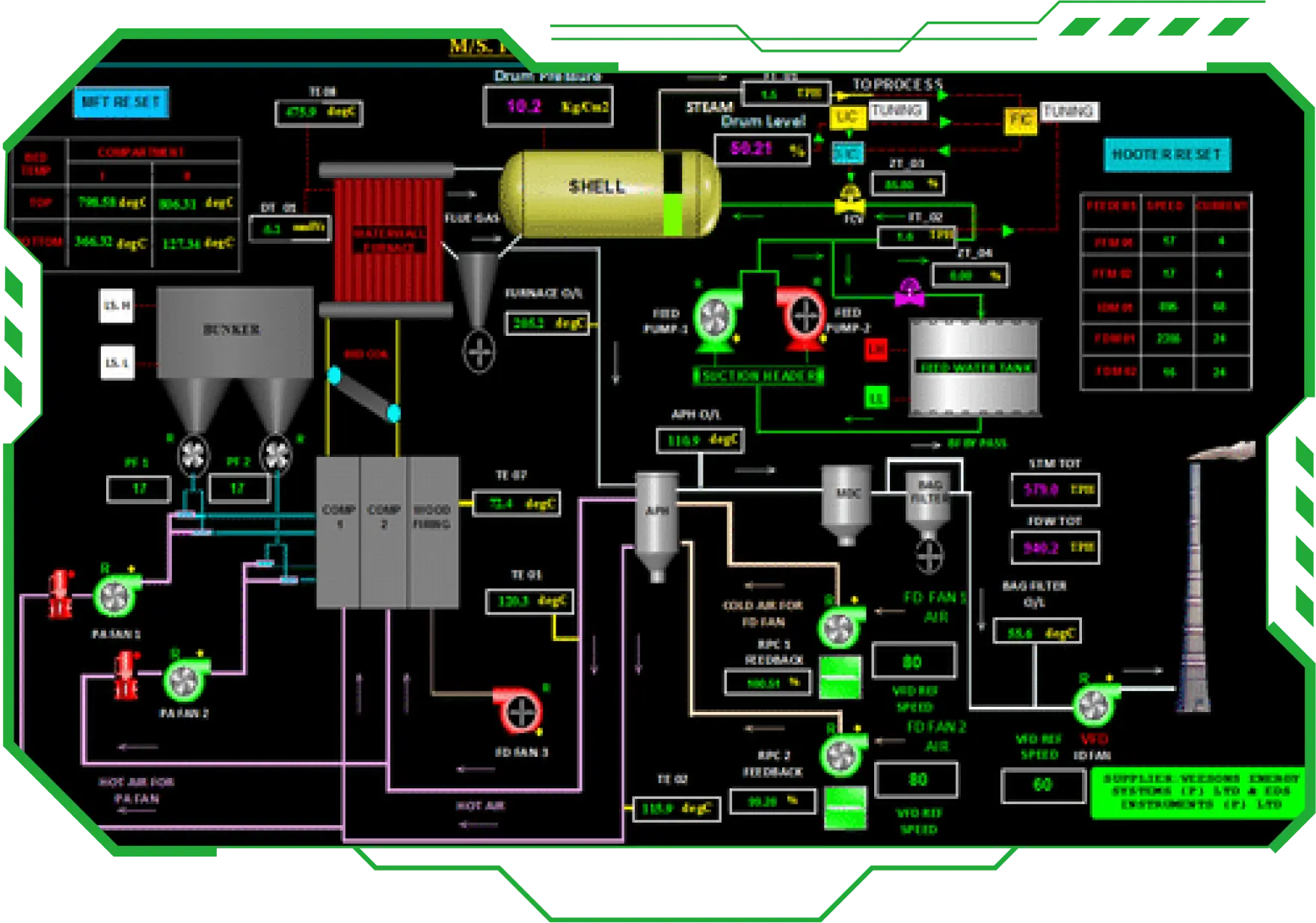

4. Detection of specific SCADA interface activities, including component recognition & OCR.

5. Seamless integration with existing workflows and systems.

Our Solution

Developed an AI-driven monitoring system utilizing the NVIDIA Jetson Nano platform to capture and analyze SCADA system outputs.

Implemented a Cloud MongoDB database for secure, real-time data storage.

Utilized OpenCV for image preprocessing, PyTorch for deep learning-based activity recognition, and Tesseract OCR for text recognition.

Integrated Node-RED for workflow management and real-time data visualization using MQTT.

Developed scripts for system initialization, logging, and maintenance on the Jetson Nano hardware.

Used template matching, feature detection, and machine learning for accurate component detection and continuous learning mechanisms.

About the

Technology Used

The project leveraged the NVIDIA Jetson Nano platform for capturing and analyzing SCADA system outputs. Key technologies included GStreamer for video capture, OpenCV for image preprocessing, PyTorch for deep learning-based activity recognition, and Tesseract OCR for text recognition. A Cloud MongoDB database was implemented for secure, real-time data storage, and Node-RED was used for workflow management and real-time data visualization using MQTT.

SCADA

Design Process

01

Discover

User Research /

In-Depth interviews

02

Design

Product Hypothesis /

User Stories

03

Develop

Style Guide /

Hi-Fi Wireframe

04

Deliver

User Interface /

Adaptive Design

Revolutionizing Desalination

with AI-Driven SCADA Monitoring

The world’s largest floating desalination plant required an advanced solution to enhance operational efficiency, ensure proactive maintenance, and improve system reliability.

Results

Enhanced Monitoring: Provided real-time insights into SCADA activities without network access, reducing response times by 40%.

Operational Efficiency: Reduced downtime by 30% and maintenance costs by 25% through proactive monitoring.

Improved Security: Ensured secure data handling and storage, decreasing security incidents by 50%.

Comprehensive Analytics: Delivered a detailed analytics dashboard for informed decision-making, improving operational decision accuracy.

Current Status

The AI-driven SCADA system monitoring solution is currently deployed at the world’s largest floating desalination plant, delivering real-time operational insights and enhancing the plant’s overall efficiency and reliability. The solution continues to provide significant improvements in monitoring, operational efficiency, and security.