Automated Water Filling System

Automated Water

Filling System

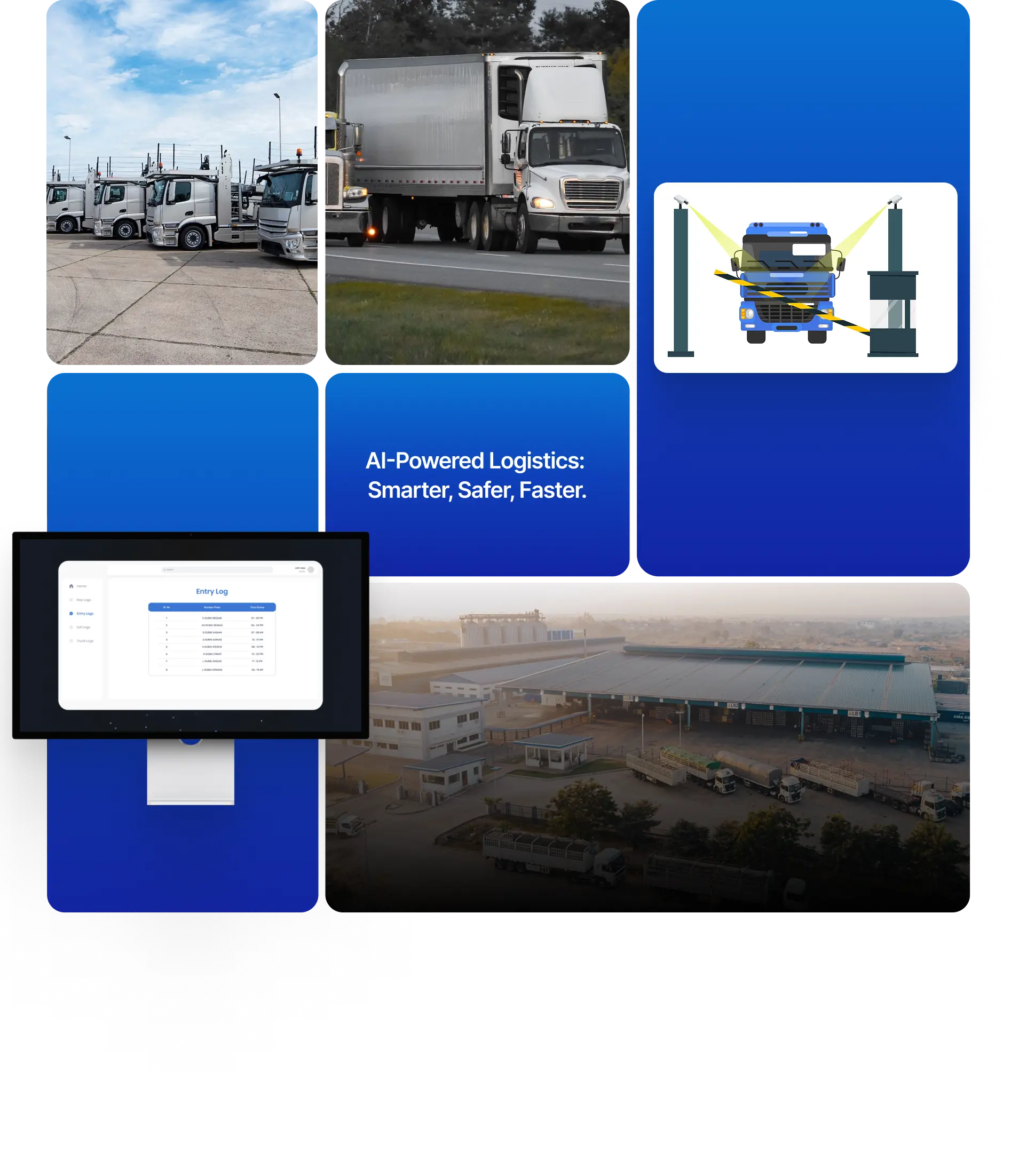

In a pioneering project set within the world’s first Cognitive City, an advanced, AI-powered automation system has been implemented to transform the water filling process. Traditional manual methods, which were inefficient and error-prone, have been replaced by a cutting-edge solution that leverages artificial intelligence, computer vision, and a robust integration of hardware and software technologies. This initiative not only optimizes operational efficiency and safety but also demonstrates the transformative potential of cognitive technologies in urban infrastructure.

TECH STACK

CLIENT

Saudi Logistics Provider

SERVICE PROVIDED

System Automation, AI and Computer Vision Implementation

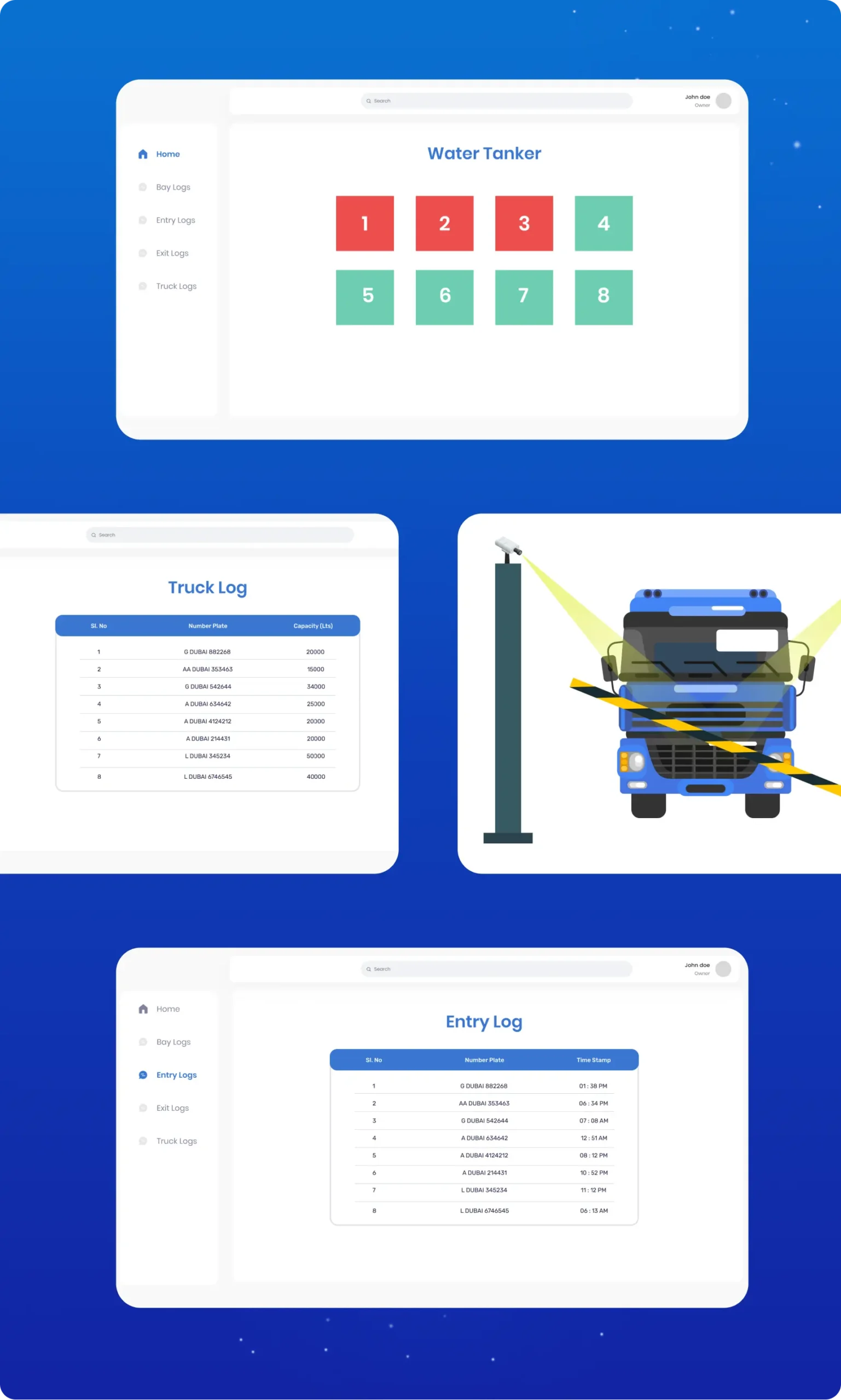

This technology is an AI-driven automated water filling system that utilizes computer vision, ALPR, and a real-time dashboard to enhance efficiency, safety, and accuracy for  logistics operations in tanker bay areas.

logistics operations in tanker bay areas.

The Problems

- Inefficiency: Manual data entry and constant monitoring resulted in slow and error-prone processes.

- Alignment Issues: Drivers struggled with aligning container lids with filling nozzles, leading to delays and safety concerns.

- Data Gaps: The absence of real-time data on bay occupancy and truck capacities hindered effective management.

- Error-Prone Logging: Manual recording of entry and exit times increased the likelihood of inaccuracies in reporting.

Smart Solutions,

Seamless Operations

Key Requirements

- AI-Powered Recognition: Utilize AI to recognize license plates and verify container alignment.

- Robust Backend: Employ a Node.js backend for system control, data management, and SCADA integration.

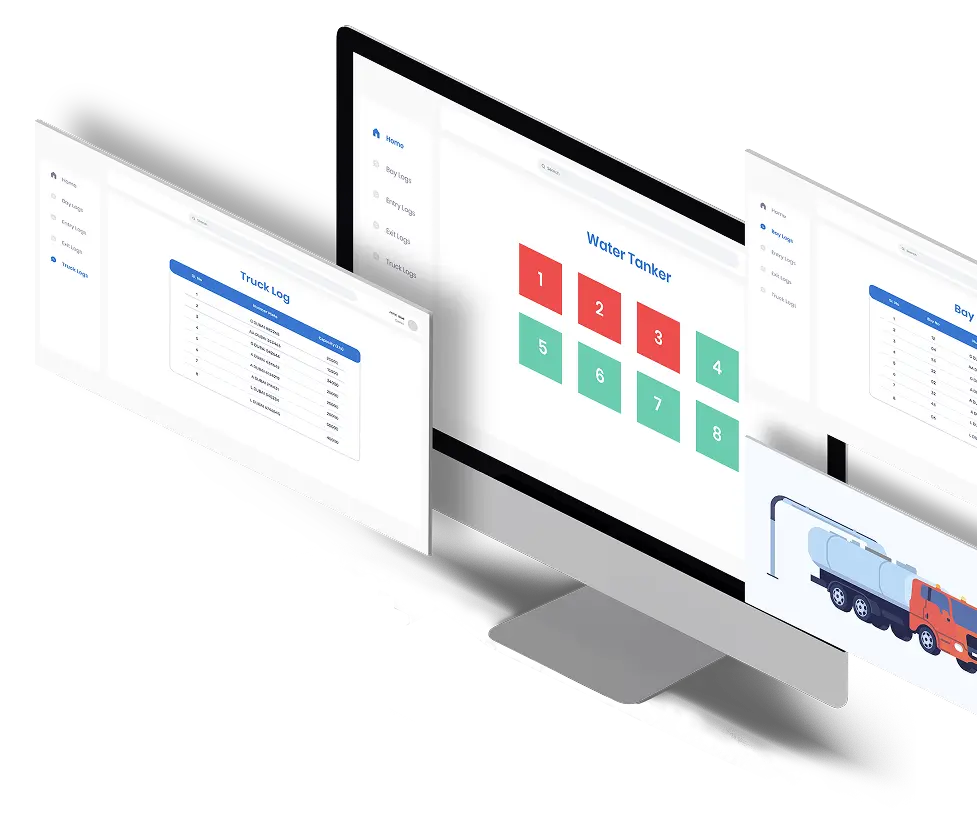

- Real-Time Dashboard: Develop a React-based dashboard for monitoring and control in real time.

- Efficient Data Storage: Implement a MySQL database for secure data storage and retrieval.

- Query Capabilities: Enable real-time queries based on datetime, bay, and truck license plate.

- Driver Input Interface: Provide an interface for drivers to enter truck container capacities.

- Computer Vision Integration: Leverage ALPR and computer vision libraries to enhance accuracy.

- Comprehensive Documentation: Document the system architecture, connectivity, implementation, and technical specifications thoroughly.

Technology Used

The system is built on advanced AI and computer vision techniques. ALPR technology is used for accurate license plate recognition, while image processing algorithms verify container alignment. A Node.js backend manages data and controls system operations, and a React dashboard provides an intuitive interface for real-time monitoring. The system’s MySQL database ensures efficient data handling, and full SCADA integration supports safe operational processes. Technologies such as Nvidia T4 GPUs, GStreamer, and SIFT/ORB feature detection further enhance performance, making it a landmark project in cognitive urban infrastructure.

Our Solution

Entry Gate Recognition:

Trucks entering the bay area have their license plates recognized using ALPR technology.

Capacity Input:

Drivers provide information about the truck's capacity, which is stored in the database.

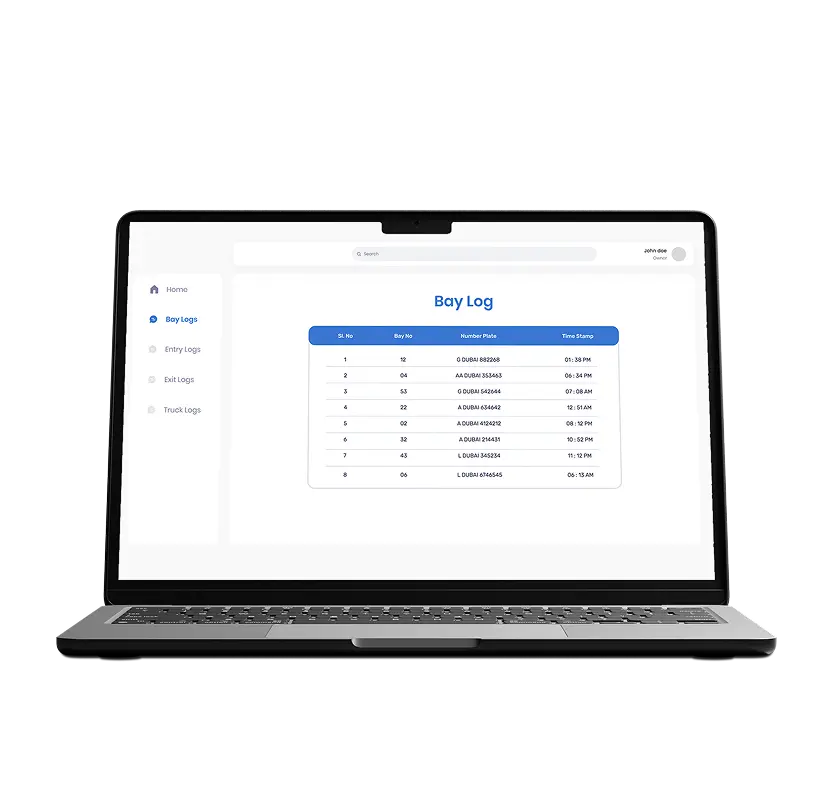

Bay Assignment:

Drivers check the dashboard to find an empty bay and proceed to that bay.

Bay Station Recognition:

A camera in the bay records the truck's license plate using ALPR.

Driver Guidance:

Displays guide drivers to properly align the container's lid with the nozzle.

Alignment Verification:

The AI application verifies the alignment using computer vision.

Filling Initiation:

If the alignment is correct, a green light signals the driver to proceed. The AI checks if the pipe is properly inserted and signals the SCADA system to open the valve.

Filling Process:

After filling, the dashboard prompts the driver to manually close the container lid.

Exit Gate Recognition:

The driver exits the bay area, and their license plate is recognized again at the exit gate using ALPR.

Data Logging:

All relevant data, including entry and exit records, is logged and stored for future reference and reporting.

Technology Behind the Transformation

With a Node.js backend, React-based dashboard, and MySQL database, we’ve built a robust system that supports real-time monitoring, efficient data management, and comprehensive reporting. Powered by AI and computer vision, our solution ensures every truck is aligned and filled with precision.

Where Innovation Meets

Automation to Revolutionize

Logistics Efficiency

With the AI-Driven Logistics Revolution, every process matters. Elevate efficiency, ensure safety, and redefine operational excellence like never before. Transform traditional workflows into automated solutions, and let this cutting-edge technology pave the way for a smarter, faster, and more sustainable future.

Efficiency Elevated,

Logistics Revolutionized.

Results

Smarter Workflows, Safer Outcomes.

The automated water filling system has been successfully deployed in Neom City and is currently operational, delivering the anticipated benefits to the client. The system has significantly improved the efficiency, safety, and accuracy of the water filling process.

Reduced Labor

Costs

Automation reduced the need for manual monitoring and data entry by 40%.

Improved

Safety

Automated alignment verification minimized safety hazards, reducing incidents by 30%.

Driver

Assistance

Visual guidance and real-time feedback enhanced the overall user experience, increasing efficiency by 25%.

Enhanced Data

Accuracy

Real-time data logging and querying improved reporting accuracy by 35%.