Automation Using Computer Vision for Largest Rail Manufacturer

AI-Powered DEFECT Detection and quality control in manufacturing

A manufacturing giant in India producing railway tracks needed to automate their testing process to enhance quality and efficiency. The manual testing of railway tracks was time-consuming and prone to human error. The developed solution involved using computer vision to automate the testing process, significantly reducing testing time and improving accuracy.

CLIENT

Patil Rail Group

SERVICE PROVIDED

AI-Powered QC In Manufacturing

Patil Rail Group is transforming railway track testing with groundbreaking automated technology that uses computer vision to boost accuracy and slash testing time.

The Problems

Brick and mortar stores need a robust method to accurately track and analyze customer behavior to:

- The manual testing process for railway tracks was time-consuming, taking up to 10 minutes per track, and involved thousands of tracks daily.

- The manual process was prone to human error, affecting the quality and reliability of the railway tracks.

- There was a need for a centralized system to store and access the details of each railway track for future reference.

- The solution needed to work effectively in the specific environment and conditions of the manufacturing plant.

Innovation Driving

Railways Forward

Key Requirements

- Development of a solution to automate the testing process.

- Accurate detection of the radius of holes in the railway tracks.

- Reduction of testing time by 10x.

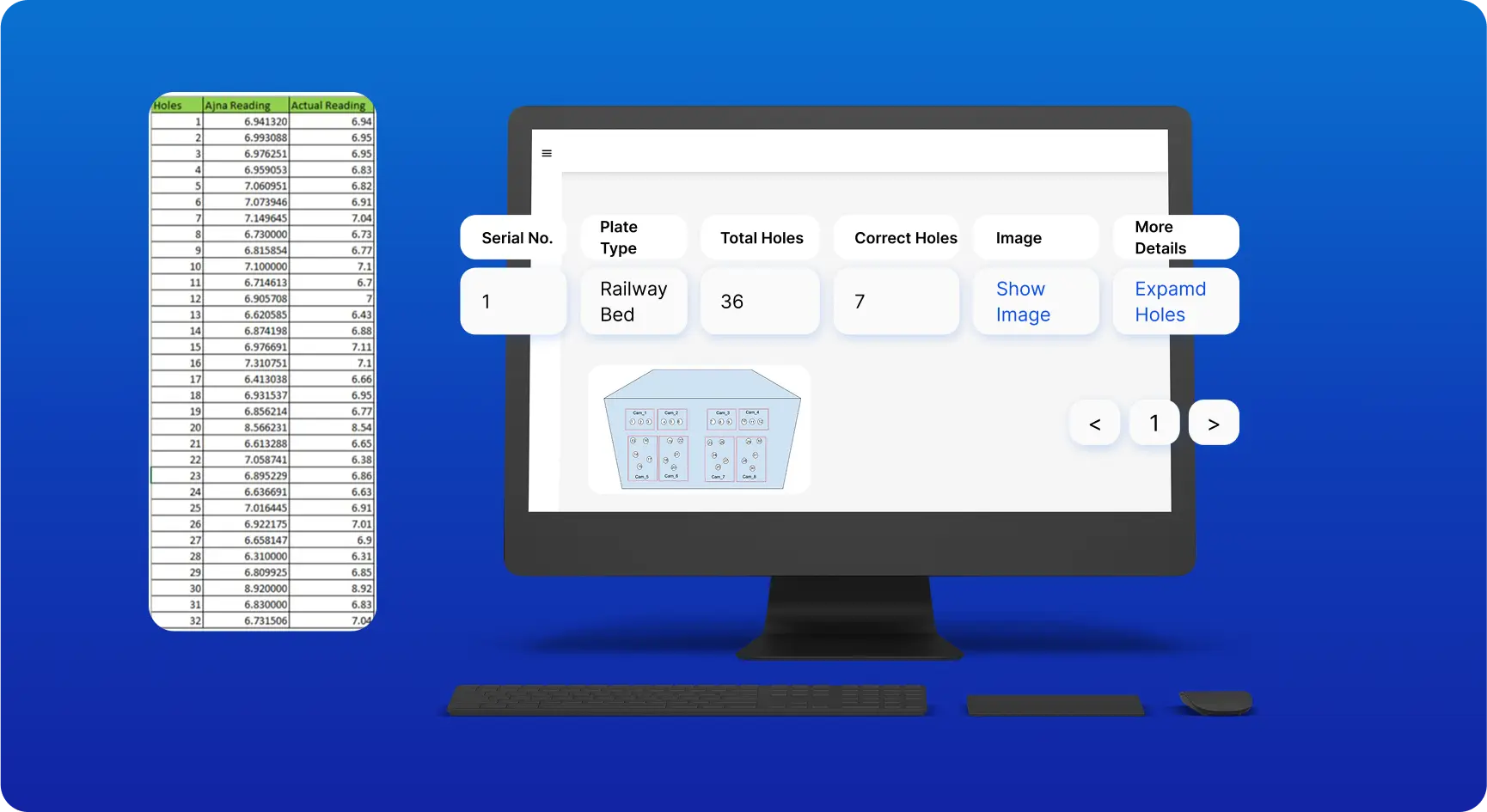

- Creation of a database to store the details of each railway track.

- Ensuring the solution works in the specific manufacturing environment.

About the Technology Used

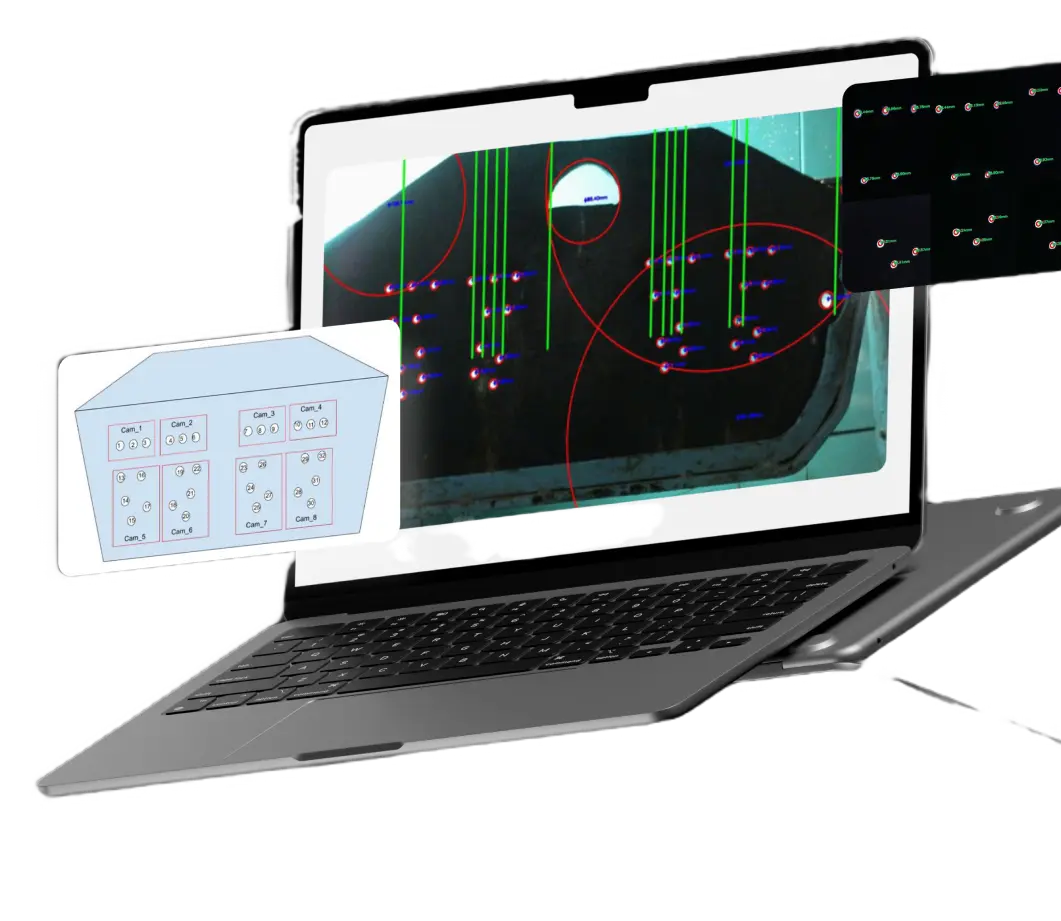

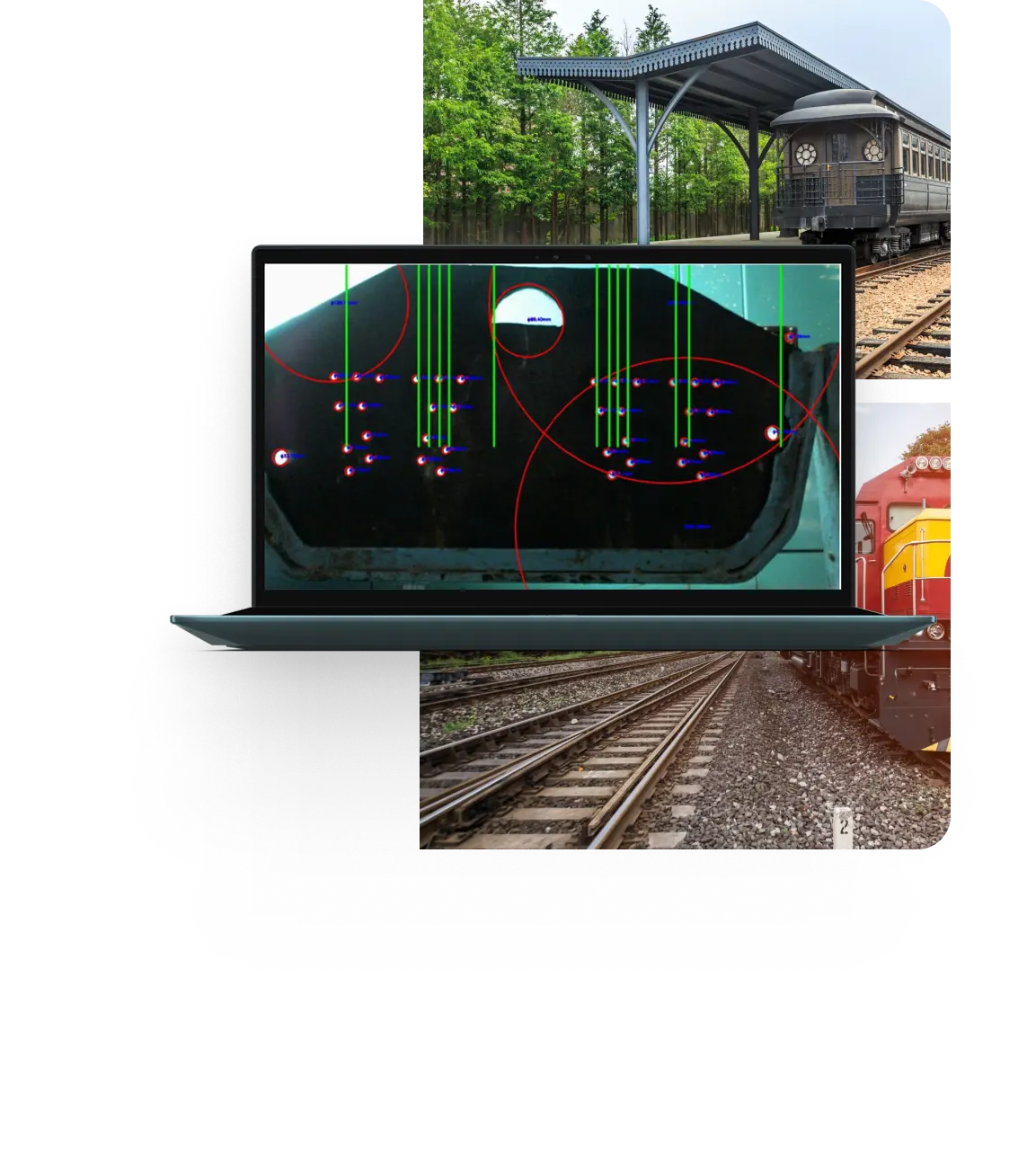

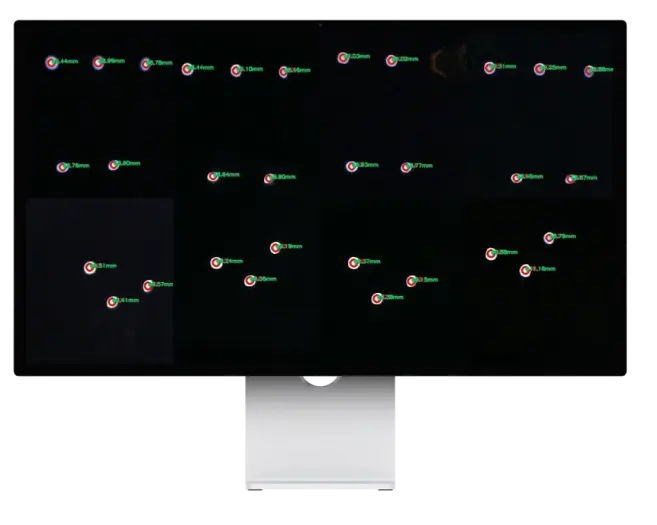

The project involved a combination of hardware and software components. A grid of cameras was used to capture images of the railway tracks, and computer vision algorithms were applied to detect the holes and measure their radii accurately. The solution was calibrated for initial use, and the details of each railway track were stored in a database accessible via a dashboard.

Our Solution

Automated Railway Track Testing System

Implemented a grid of cameras to capture images of the railway tracks and applied computer vision algorithms to detect the holes and measure their radii accurately.

Calibration of Railway Track Testing System

Calibrated the system for first-time usage and ensured it worked effectively in the specific manufacturing environment.

Database Setup & Management

Developed a database to store details of each railway track, enabling future reference and analysis.

Dashboard Setup and Management

Created a dashboard for real-time monitoring and management of the testing process.

Precision in Every Test, Efficiency in Every Track

Patil Rail Group’s automated railway track testing system has redefined how tracks are tested. Powered by advanced computer vision, the solution reduces testing time by 90%, detects defects with 85% improved accuracy, and ensures unmatched quality control. This technology not only accelerates manufacturing but also sets a new benchmark for reliability in railway infrastructure.

Development Process

01

Discover

User Research /

In-Depth interviews

02

Design

Product Hypothesis /

User Stories

03

Develop

Style Guide /

Hi-Fi Wireframe

04

Deliver

User Interface /

Adaptive Design

Where Automation Meets Rail Precision to Redefine Track Testing & Manufacturing Excellence

With the Automation Revolution in Rail Manufacturing, every second counts. Enhance track quality, streamline testing processes, and redefine manufacturing efficiency like never before. Transform traditional manual inspections into intelligent, real-time precision, and let this cutting-edge technology pave the way to a future of unmatched accuracy, reliability, and operational excellence.

Automated Excellence for

Every Railway Track.

Results

Revolutionizing Tracks, Redefining Precision.

The automated railway track testing system is fully operational, significantly improving the quality and efficiency of track analysis. The system has been installed at the manufacturing plant, with proper lighting conditions, easy usability, and network access. The solution has reduced testing time, improved accuracy, and provided a centralized data management system.

Reduced Testing

Time

Automated testing reduced the testing time by 90%, from 10 minutes to 1 minute per track.

Improved

Accuracy

Enhanced accuracy in detecting and measuring hole radii, reducing errors by 85%.

Centralized Data Management

The database and dashboard provided a centralized system for storing and accessing railway track details, improving organization and efficiency.

Enhanced Quality Control

The automated system identified defective holes, allowing for timely fixing or re-boring, improving the overall quality of the railway tracks.