Automation Using Computer Vision for Largest Rail Manufacturer

Automation Using

Computer Vision for

Overview

A manufacturing giant in India producing railway tracks needed to automate their testing process to enhance quality and efficiency. The manual testing of railway tracks was time-consuming and prone to human error. The developed solution involved using computer vision to automate the testing process, significantly reducing testing time and improving accuracy.

Problem

1. The manual testing process for railway tracks was time-consuming, taking up to 10 minutes per track, and involved thousands of tracks daily.

2. The manual process was prone to human error, affecting the quality and reliability of the railway tracks.

3. There was a need for a centralized system to store and access the details of each railway track for future reference.

4. The solution needed to work effectively in the specific environment and conditions of the manufacturing plant.

Key Requirements

About the Technology Used

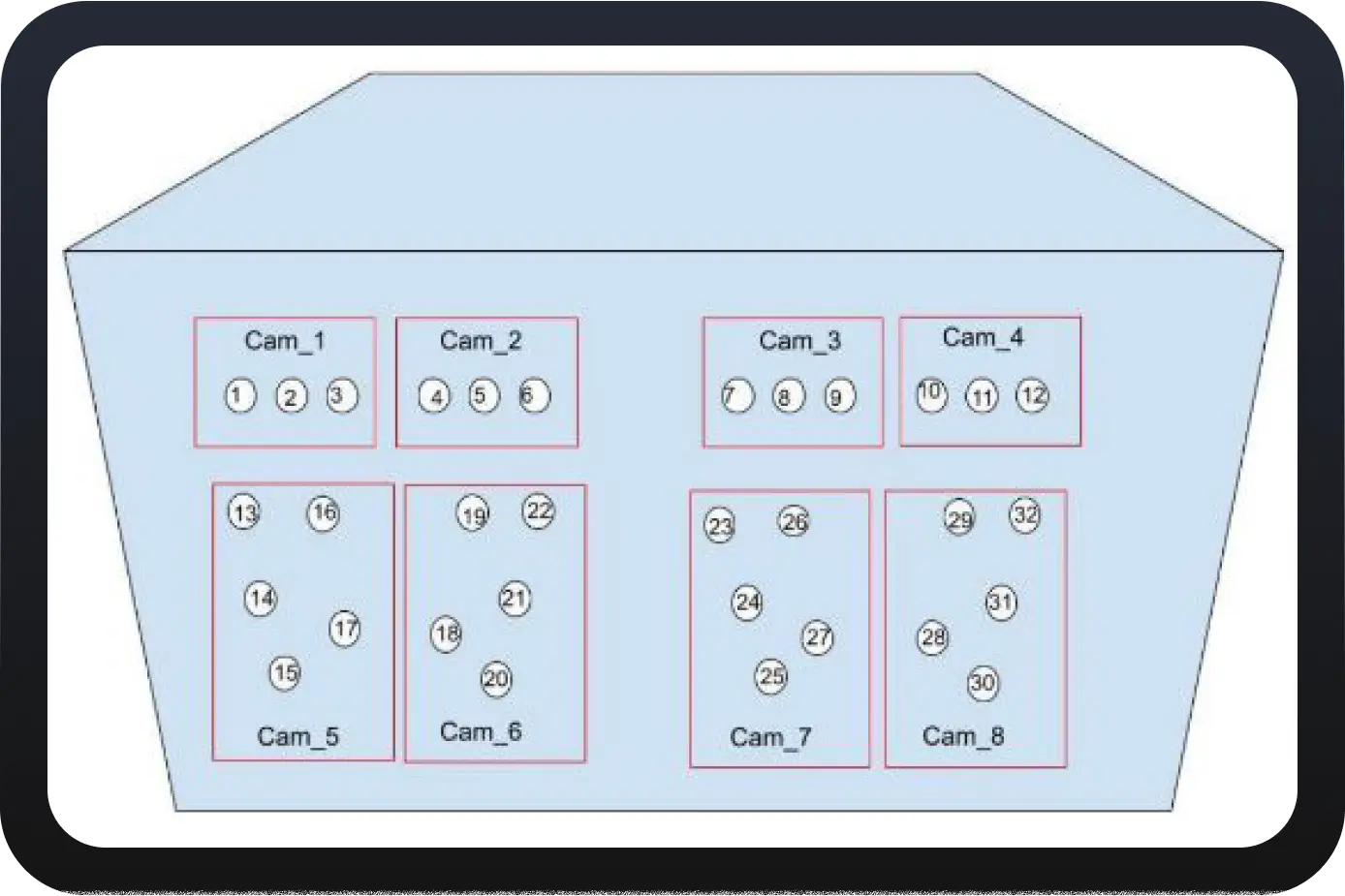

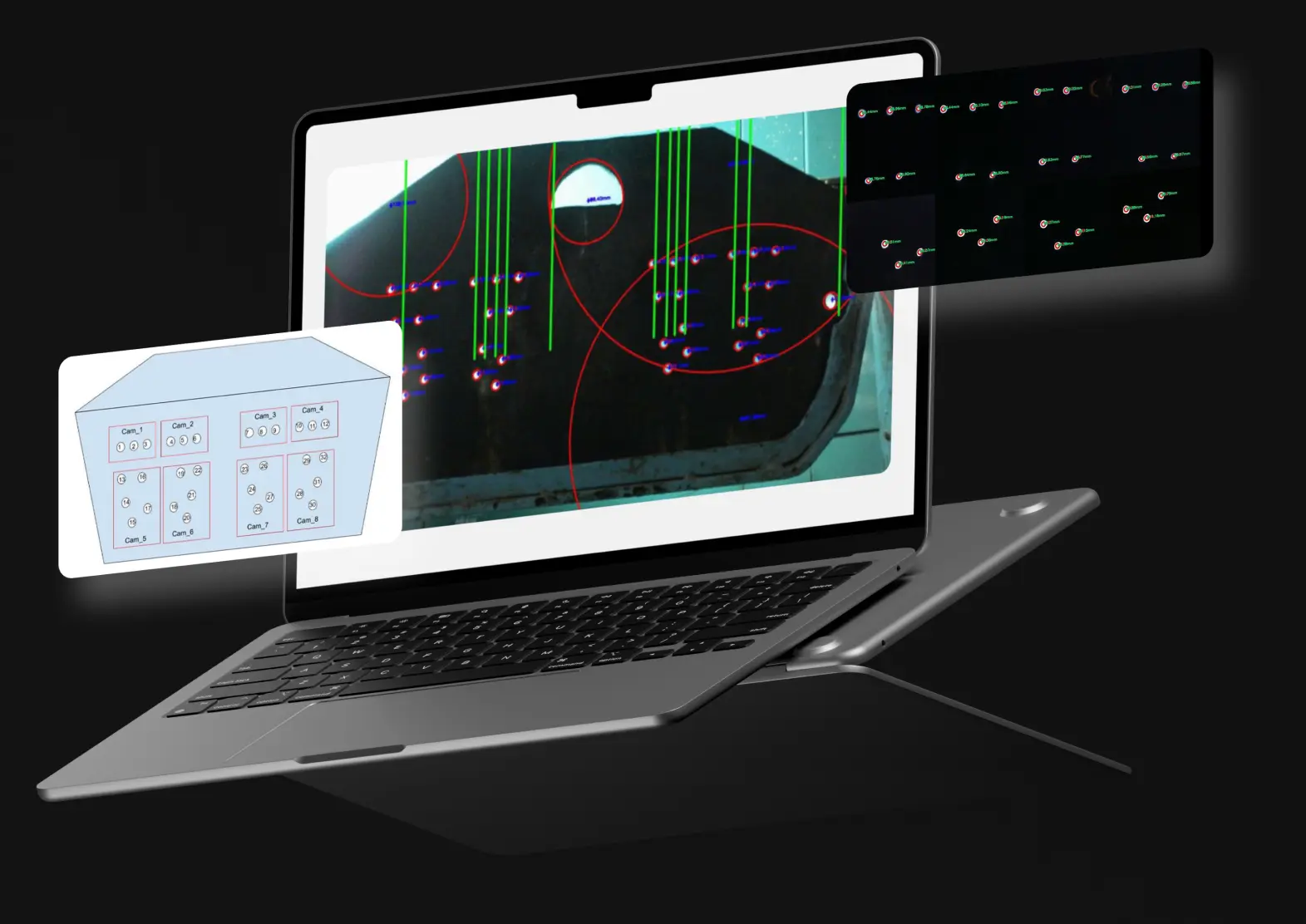

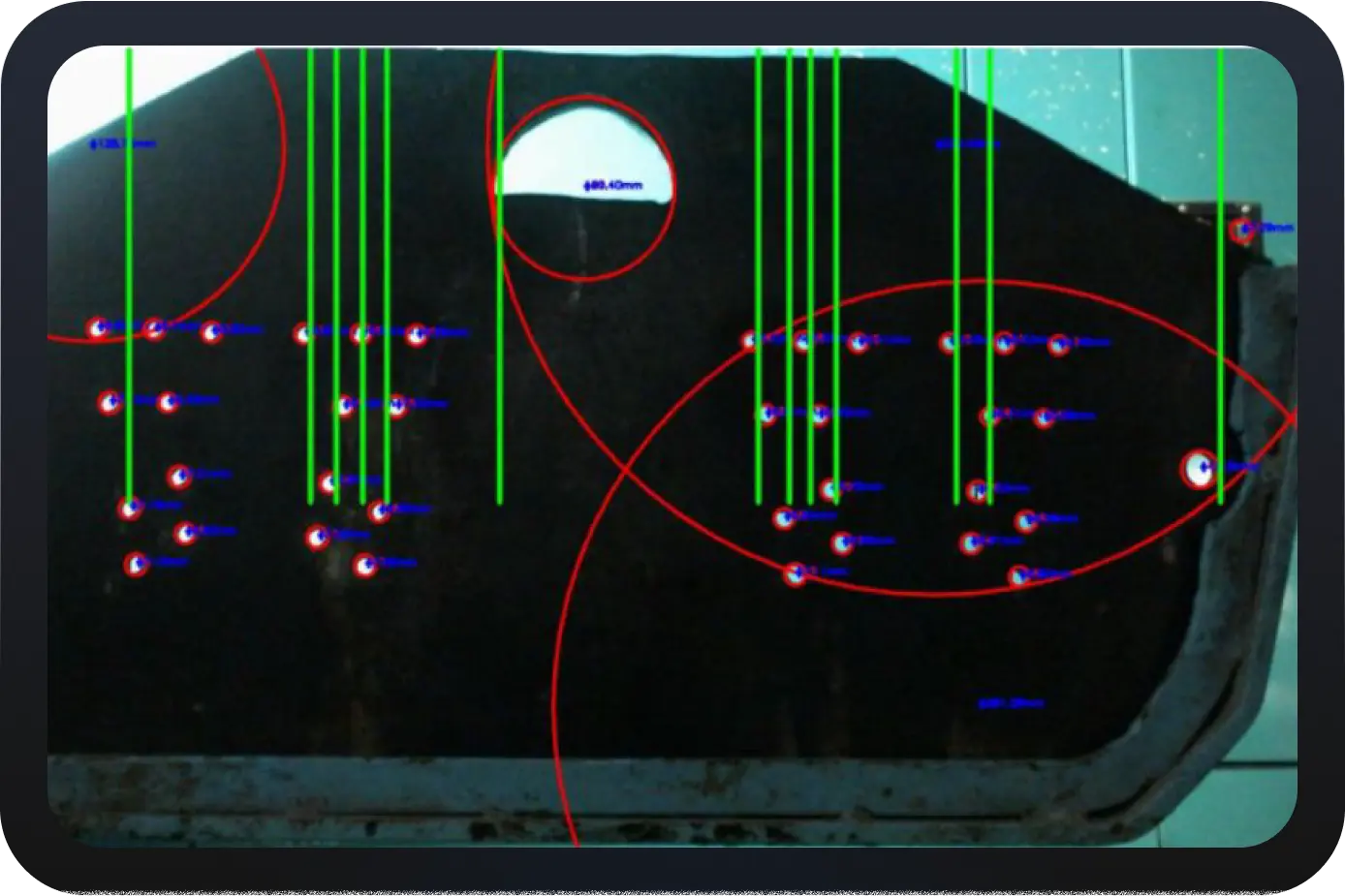

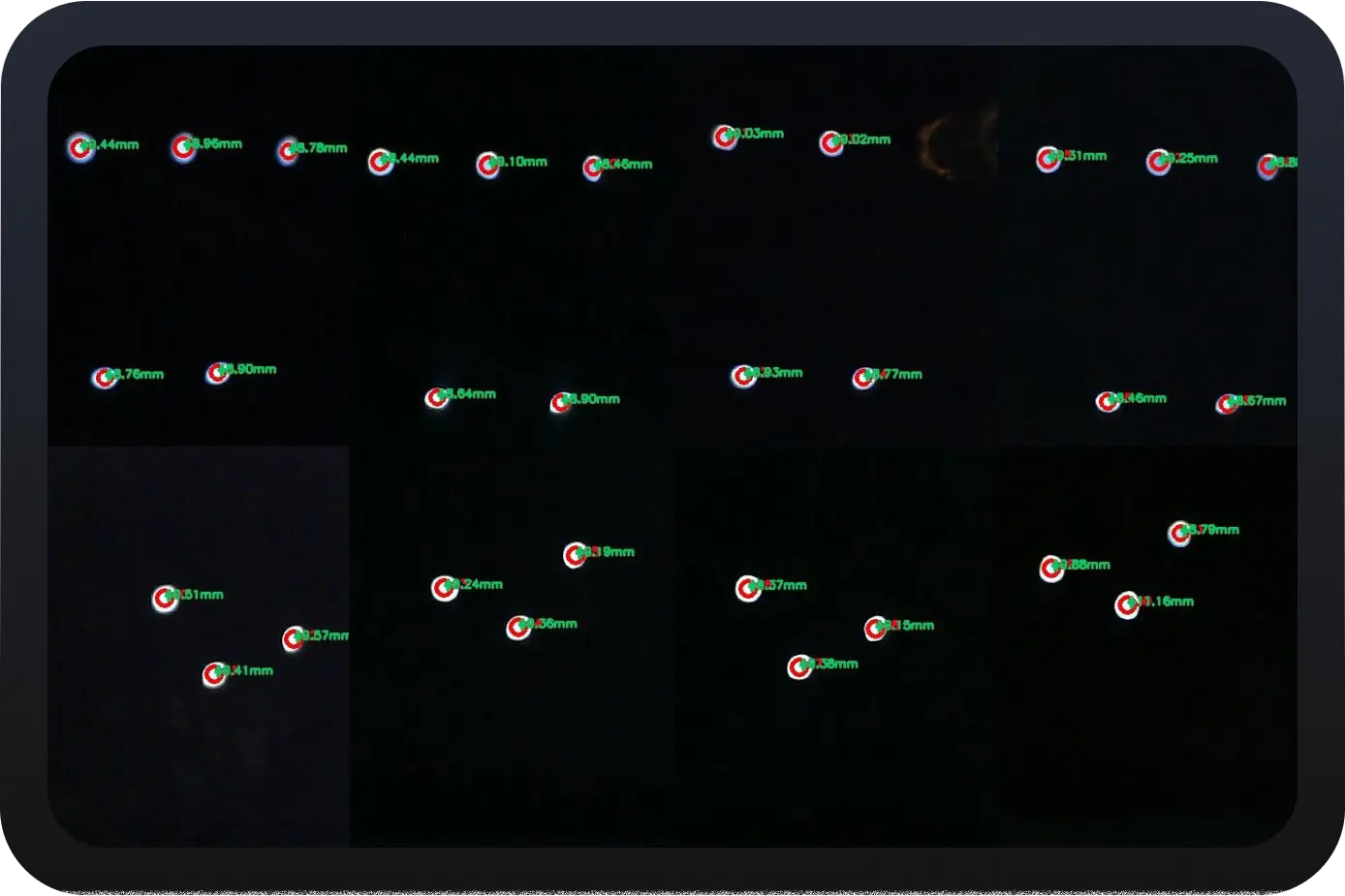

The project involved a combination of hardware and software components. A grid of cameras was used to capture images of the railway tracks, and computer vision algorithms were applied to detect the holes and measure their radii accurately. The solution was calibrated for initial use, and the details of each railway track were stored in a database accessible via a dashboard.

Solutions

- Automated Railway Track Testing System: Implemented a grid of cameras to capture images of the railway tracks and applied computer vision algorithms to detect the holes and measure their radii accurately.

- Calibration of Railway Track Testing System: Calibrated the system for first-time usage and ensured it worked effectively in the specific manufacturing environment.

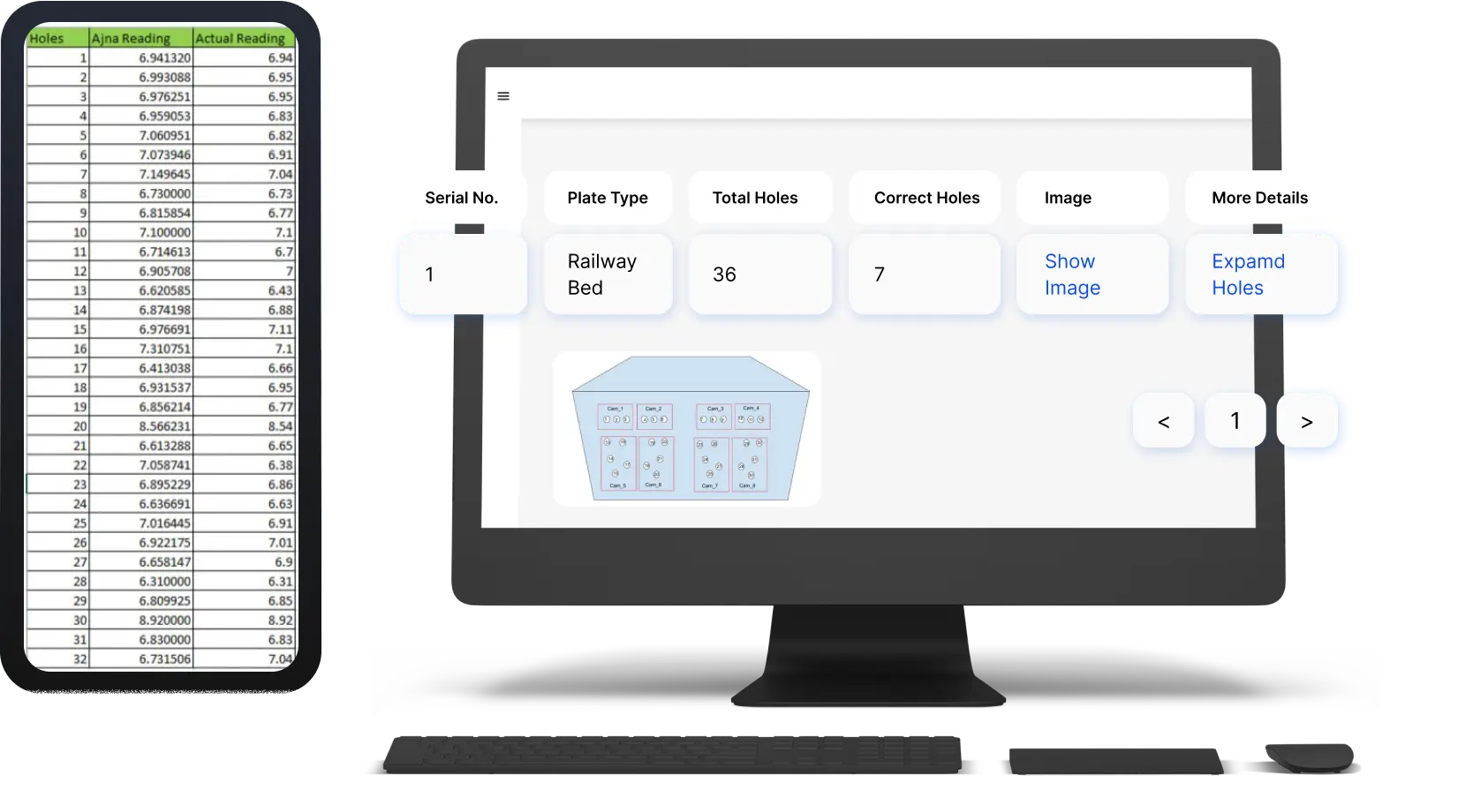

- Database Setup and Management: Developed a database to store details of each railway track, enabling future reference and analysis.

- Dashboard Setup and Management: Created a dashboard for real-time monitoring and management of the testing process.

Result

Reduced Testing Time:

Automated testing reduced the testing time by 90%, from 10 minutes to 1 minute per track.

Improved Accuracy:

Enhanced accuracy in detecting and measuring hole radii, reducing errors by 85%.

Centralized Data Management:

The database and dashboard provided a centralized system for storing and accessing railway track details, improving organization and efficiency.

Enhanced Quality Control:

The automated system identified defective holes, allowing for timely fixing or re-boring, improving the overall quality of the railway tracks.

Revolutionizing the

Quality and Efficiency of Railway Track Analysis

Current Status

The automated railway track testing system is fully operational, significantly improving the quality and efficiency of track analysis. The system has been installed at the manufacturing plant, with proper lighting conditions, easy usability, and network access. The solution has reduced testing time, improved accuracy, and provided a centralized data management system.