Introduction

In today’s fast-moving supply chain landscape, businesses in Australia rely on WMS to reduce costs, improve order accuracy, and scale operations. This guide covers what matters when choosing a WMS, who the leading providers are, and where Nyx Wolves deliver superior results.

A modern system also enhances real-time visibility, enabling managers to make faster and more informed decisions. By integrating AI and automation, WMS solutions in Australia unlock measurable ROI and competitive advantage. Companies adopting the right platform gain resilience, flexibility, and long-term scalability across global and local markets.

The Role of Supply Chain Management System (SCMS)

WMS acts as the operational backbone, synchronising receiving, putaway, picking, packing, and dispatch. In Australia, adopting a modern, Python & Django-ready platform ensures real-time visibility across locations, shorter cycle times, and higher on‑time delivery rates.

- It enables predictive demand planning and automated replenishment, helping businesses in Australia reduce stockouts and excess inventory.

- By integrating it with Python & Django, companies gain end-to-end visibility and analytics, improving decision-making and supply chain resilience.

- A scalable platform future-proofs operations in Australia, supporting omnichannel growth, compliance, and customer satisfaction.

Key Features of AI-Driven Warehouse Automation in Saudi Arabia

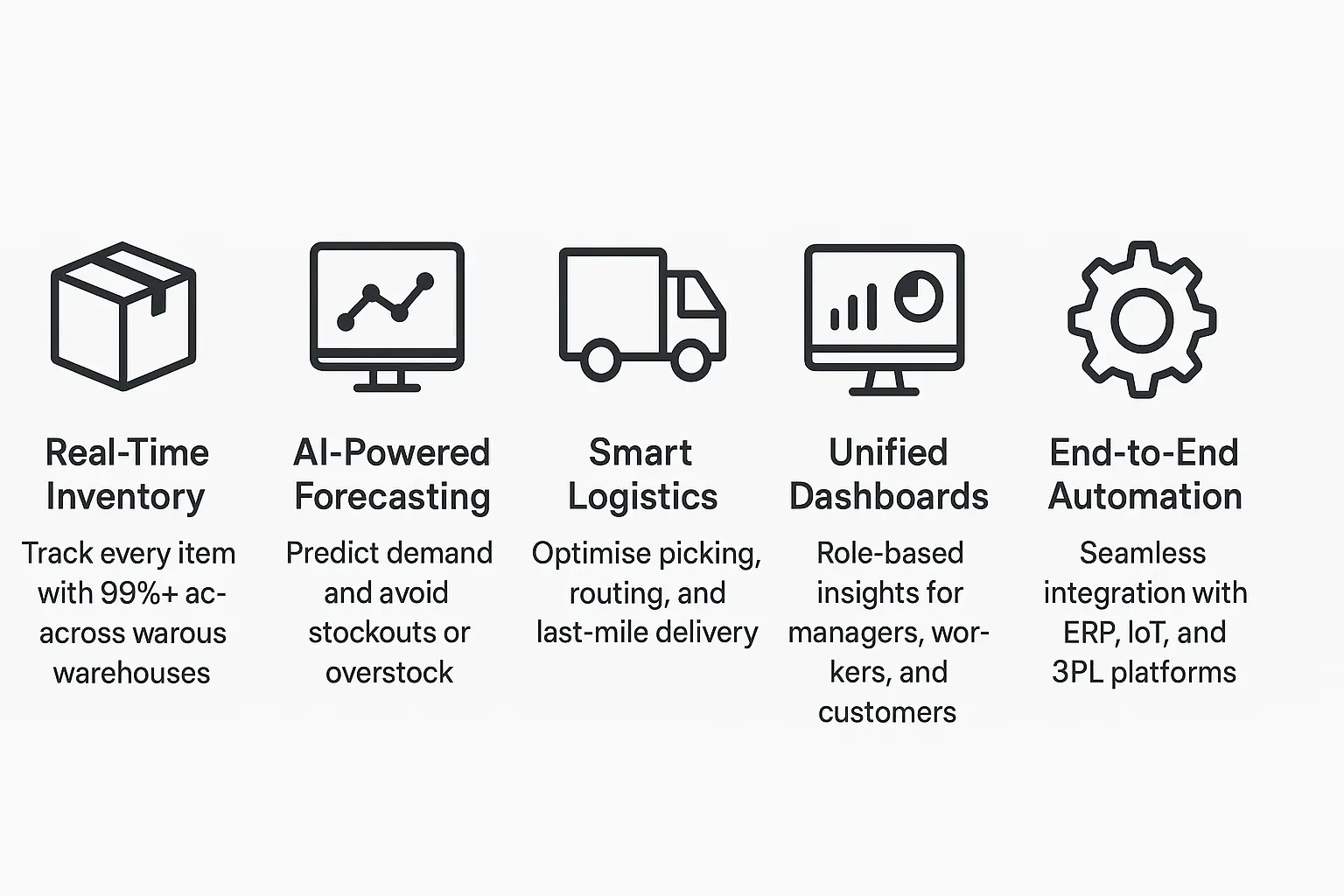

A modern WMS should include real‑time inventory tracking, barcode/RFID, mobile workflows, AI‑powered demand forecasting, smart picking, automated cycle counting, seamless ERP/marketplace integrations, and analytics built for continuous improvement.

- It supports multi-warehouse and multi-location management in Australia, ensuring unified visibility and faster order fulfilment across the network.

- AI-driven insights within the platform help optimise labour utilisation, slotting strategies, and transport planning, reducing costs and cycle times.

- With Python & Django compatibility, this system enables seamless integration with IoT devices, cloud dashboards, and third-party logistics platforms for end-to-end automation.

Popular Supply Chain Management System (SCMS) Providers in Saudi Arabia

Popular WMS vendors in Australia include Zoho Inventory, Blue Yonder Warehouse Management, and Infor WMS. Each of these providers brings unique strengths ranging from specialised industry modules to flexible deployment models and advanced integration capabilities.

Other notable vendors include Aptean Distribution ERP, SAP Extended Warehouse Management (EWM), Manhattan Warehouse Management, HighJump WMS, Microlistics WMS, Cin7 WMS, and CartonCloud.

Evaluation Factors (with clear framing)

When evaluating options across vendors such as Zoho Inventory through CartonCloud, businesses in Australia should carefully assess the following factors:

- Integration Requirements – How well WMS integrates with existing Python & Django, ERP, marketplace, and third-party logistics systems.

- Deployment Models – Whether the vendor supports cloud-based, on-premises, or hybrid deployment, and which model best aligns with security, scalability, and compliance needs in Australia.

- Customisation & Scalability – The ability of the software solutions to adapt to evolving workflows, industry-specific regulations, and expansion across multiple warehouses or locations.

- Total Cost of Ownership (TCO) – Not just upfront licensing, but also implementation services, training, support, and long-term upgrade expenses across different vendors.

Closing Statement

Selecting the right WMS vendor in Australia is ultimately about balancing immediate operational needs with future readiness, ensuring that your chosen system continues to deliver value as your business scales.

How Nyx Wolves’ Supply Chain Management System (SCMS) Outperforms Competitors

Positioning:

While Zoho Inventory offers proven capabilities in WMS, many businesses in Australia find the platform less flexible when it comes to rapid customisation, AI-driven automation, and end-to-end scalability.

Our WMS / Logistics, Supply chain / Inventory Portal unique features:

- AI-First Operations With Measurable ROI

- Shelf Vision AI – Overhead and shelf-level cameras automatically detect check-in/check-out events, identify misplaced items, and trigger restock alerts without human scanning.

- Demand Forecasting – Predicts sales trends and seasonal spikes with up to 95% accuracy, reducing overstock and stockouts by 25–35%.

- Smart Picking Optimisation – AI generates optimal picking sequences and routes, reducing picking time by 40%.

- Predictive Maintenance – Fleet sensors and usage data forecast service needs, cutting breakdown-related downtime by 20–30%.

- Anomaly Detection – Flags unexpected movements, unusual demand patterns, or shrinkage in real time.

- Dynamic Replenishment – Automatically raises POs when forecast thresholds are breached.

- Intelligent Cycle Counting – Continuous, automated inventory audits while operations remain active, improving count accuracy to 99%+.

- AI-Driven Route Optimisation – Plans last-mile delivery paths to minimise fuel cost and improve on-time delivery rates by 15–20%.

- Real-Time Visibility for All Stakeholders

- Role-Specific Access – Tailored dashboards and permissions for customers, employees, and managers.

- Instant Notifications – Stock levels, delivery status, and order updates pushed instantly via web, app, or handheld devices.

- Cross-Device Access – Operates smoothly on barcode handhelds, tablets, and mobile.

- Barcode-Powered Accuracy With Full Automation

- Barcode-First Validation – Every transaction scanned, logged, and tracked for near-zero errors.

- Automated Shelf Camera Scans – No manual intervention for standard restock checks.

- Error Reduction – Automated validation processes cut order errors by up to 90%.

- All-in-One Fleet, Inventory & Order Management

- Single Integrated Platform – POs, invoices, delivery slips, and fleet schedules all under one hood.

- Last-Mile Delivery Integration – Real-time tracking and proof of delivery for customers.

- Service & Maintenance Hub – Tracks vehicle and equipment upkeep, linking it to operational schedules.

- Fully Customisable, Bespoke Solutions

- Tailored Workflows – Match your exact operational flow and industry requirements.

- Scalable Architecture – Easily extend to new warehouses, fleets, or locations.

- Sector-Specific Modules – From manufacturing to retail, built to fit your business.

How Nyx Wolves beats SAP EWM:

With AI‑first operations, Shelf Vision AI, 95%+ demand forecasting accuracy, smart picking (−40% picking time), predictive maintenance (−20–30% downtime), automated cycle counting (99%+ accuracy), and AI route optimisation (+15–20% on‑time delivery), Nyx Wolves ships faster value with tailored workflows and rapid implementation.

Real-World Impact of Modern Supply Chain Software in Saudi Arabia

Teams adopting Nyx Wolves in Australia report fewer stockouts, faster turnarounds, clearer stakeholder visibility, and measurable ROI. From retail to 3PL, the platform reduces manual touches while maintaining audit‑ready accuracy.

Conclusion

If you’re evaluating WMS in Australia, prioritise AI capability, integration depth, and time‑to‑value. Nyx Wolves combines advanced automation with bespoke design, so your process defines the system, not the other way around.

Start smarter supply chain operations today

Recent Posts

How a Custom WMS helped UPS automate 2.4M Transactions

Cost of building an AI Recruitment tool

Upgrade your warehouse with Nyx Wolves

Partner with Nyx Wolves

As an experienced provider of AI and IoT software solutions, Nyx Wolves is committed to driving your digital transformation journey.

Your benefits:

- Client-oriented

- Independent

- Competent

- Results-driven

- Problem-solving

- Transparent

What happens next?

We Schedule a call at your convenience

We do a discovery and consulting meting

We prepare a proposal

Schedule a Free Consultation

See Our Case Studies

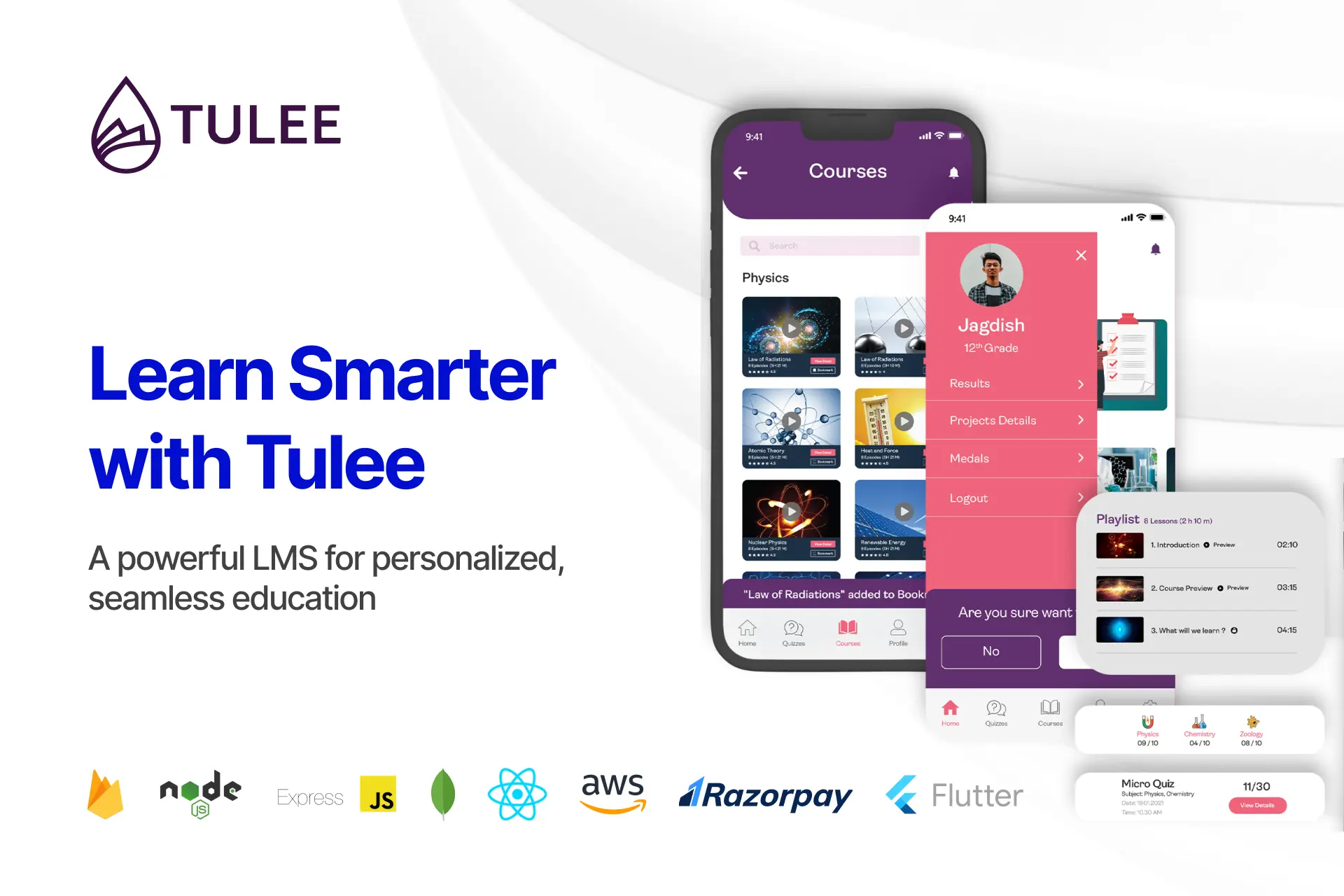

AI-powered job matching platform

PerpectV AI-Powered Job Matching Platform for Leading South African

No-code web based AR Platform

Revolutionizing Online Product Showcase with No-Code WebAR Xarwin is

Case Study – Ecostay

Srivalli Ecostays offers a unique hospitality experience, allowing guests