Safety Insights – A Solution for Workplace Compliance and Safety

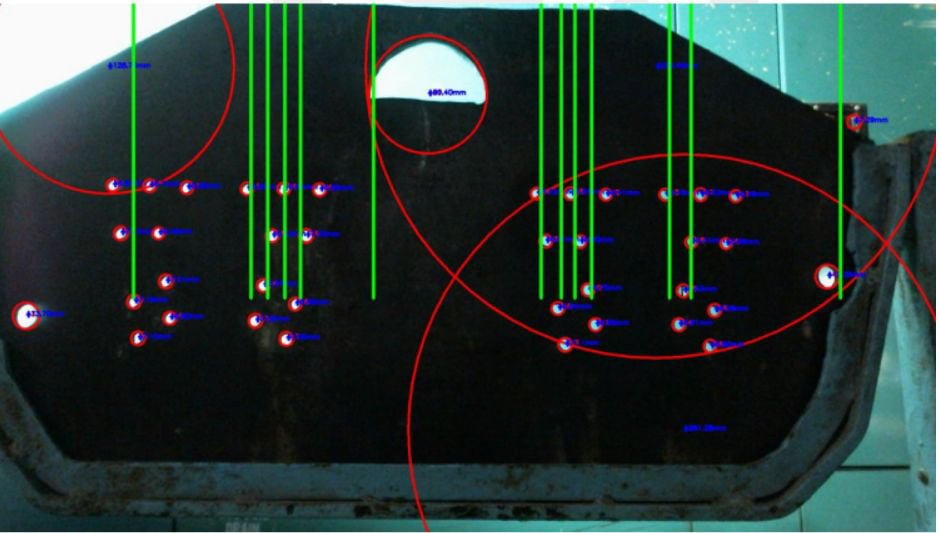

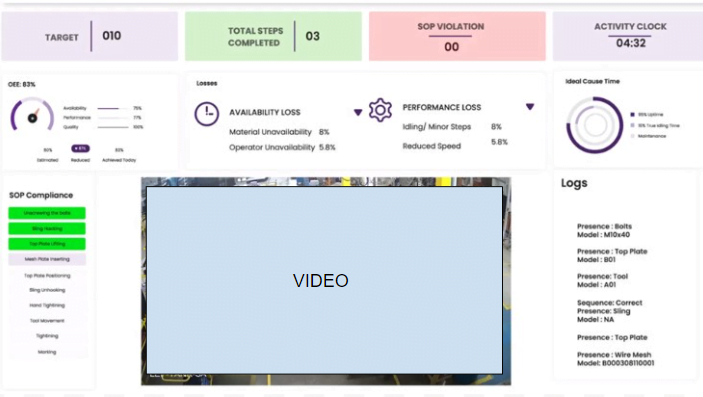

Providing real-time alerts and analytics for workplace safety and compliance Safety Insights – A Solution for Workplace Compliance and Safety Workplace safety and compliance are critical issues that every business must address. The traditional approach to monitor safety and compliance is through manual audits, which are time-consuming and prone to errors. Problem Workplace safety and compliance are critical issues that every business must address. The traditional approach to monitor safety and compliance is through manual audits, which are time-consuming and prone to errors. There is a need for a solution that can monitor the workplace in real-time and provide alerts and analytics to improve safety and compliance. Key Requirements The solution should use existing CCTV cameras to monitor the workplace and detect and track the workflow. It should be powered by artificial intelligence and should be able to learn from previous data to identify correct processes and mark discrepancies. The solution should have multiple deployment options, including edge, on-premise, and cloud. It should have a dashboard for data visualisation and reporting. Data Privacy The Ajna Architecture has 100% privacy built-in as 100% of the video processing is happening at the edge, at the customer’s location, and 0% of the video feed is uploaded to the cloud. In addition, 0% of the video feed is stored locally for future processing, however, on a requirement basis, the video can be stored locally. 100% processing occurs in real-time on the Ajna Edge Device. The solution is GDPR compliant. Results The solution has a detection accuracy of more than 90% and has helped businesses improve safety and compliance in the workplace. The dashboard provides real-time alerts and analytics, which has helped businesses identify and resolve safety and compliance issues in real-time. Logic The solution is an artificial intelligence-enabled solution that uses existing CCTV cameras to detect and track the workflow of the workplace. The AI is trained using previous data to identify the correct process and mark discrepancies. The solution has multiple deployment options, including edge, on-premise, and cloud. The dashboard provides real-time alerts and analytics to improve safety and compliance. Custom Object Detection All underlying architecture for any object detection is already built. It will take approximately 2-3 weeks to train any new object Eg. Smoke, New PPE. The accuracy is based on the correct training data and camera angles in which the videos are recorded. Intended Outcomes The intended outcomes of the solution are to be able to analyze and report all the observations decided with the client and deploy a system that can monitor and produce safety data of the business. Quality/Accuracy The detection accuracy of the solution is more than 90%, which has helped businesses improve safety and compliance in the workplace. Services The solution provides real-time alerts and analytics to improve safety and compliance in the workplace. It uses existing CCTV cameras to detect and track the workflow and provides real-time alerts and analytics to improve safety and compliance. Technology