MANUFACTURING

Revolutionize Your

Manufacturing Operations

with AI & IoT Solutions

Explore Our AI & IoT Solutions for Manufacturing

OVERVIEW

Overview

In today’s fast-paced and competitive manufacturing landscape, the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies has become increasingly crucial. The synergy between AI and IoT offers manufacturers unprecedented opportunities to enhance efficiency, optimize processes, and achieve new levels of productivity. Explore the various applications of AI & IoT in the manufacturing industry below:

Utilize AI-powered predictive analytics to detect equipment failures before they occur

IoT sensors collect real-time data for monitoring machine health and performance

Reduce downtime, optimize maintenance schedules, and extend equipment lifespan

AI algorithms analyze visual data from cameras and sensors for defect detection

Real-time monitoring ensures consistent product quality and reduces waste

Improve accuracy and speed of inspections, enhancing overall production efficiency

IoT-enabled tracking and monitoring of inventory

and shipments

AI algorithms analyze supply chain data for demand forecasting and inventory optimization

Streamline logistics, reduce stockouts, and improve

order fulfillment

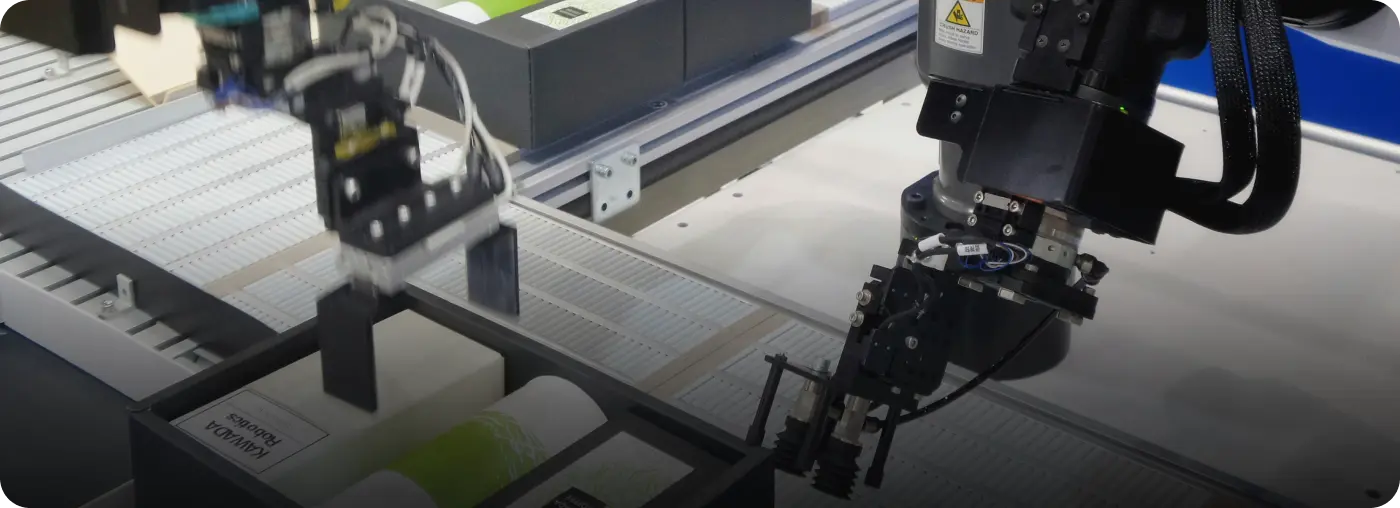

AI-powered robots and Autonomous Guided Vehicles (AGVs) automate material handling

IoT connectivity enables centralized control and coordination of robot fleets

Enhance efficiency, reduce human error, and improve

workplace safety

IoT sensors monitor energy consumption and equipment efficiency

AI algorithms optimize energy usage, reduce waste, and identify energy-saving opportunities

Achieve sustainability goals, lower operating costs, and minimize environmental impact

IoT devices and AI-powered analytics enable real-time data collection and analysis

Improve production planning, optimize resource allocation, and enhance overall operational efficiency

Enable proactive decision-making and agile response to changing market demands

AI-powered cobots (collaborative robots) work alongside human operators

IoT connectivity enables seamless communication and interaction between humans and machines

Enhance productivity, worker safety, and job satisfaction

AI and IoT technologies track product performance and customer usage data

Enable predictive maintenance, product improvement, and personalized customer experiences

Optimize product lifecycle, reduce warranty costs, and drive customer satisfaction

HOW

How We Can Help Implement These Applications

At Nyx Wolves, we specialize in delivering tailored AI & IoT solutions to the manufacturing industry. With our expertise and deep understanding of the manufacturing landscape, we can assist you in successfully implementing these applications and driving digital transformation. Here’s how we can help:

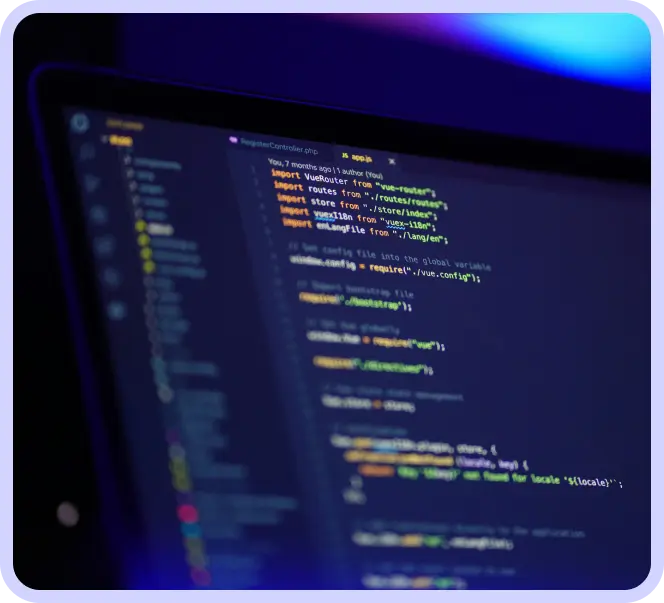

Custom Solution Development

- Our experienced team of AI and IoT specialists will work closely with you to understand your specific requirements and challenges.

- We will design and develop custom solutions that align with your manufacturing processes and goals.

- From AI algorithms and machine learning models to IoT sensor integration and connectivity, we'll ensure a seamless implementation.

Integration with Existing Systems

Integration with Existing Systems

- We have extensive experience in integrating AI and IoT solutions with existing manufacturing systems, such as ERP and MES platforms.

- Our experts will ensure smooth data exchange, synchronization, and interoperability between different systems and devices.

- We'll maximize the value of your existing technology investments while augmenting them with AI and IoT capabilities.

Scalable and Secure Architecture

Scalable and Secure Architecture

- Our team will architect scalable and secure solutions that can handle the volume, velocity, and variety of data generated by AI and IoT applications.

- We prioritize data privacy, confidentiality, and compliance with industry regulations.

- Whether it's cloud-based infrastructure, edge computing, or hybrid deployments, we'll design the optimal architecture for your needs.

Training and Support

Scalable and Secure Architecture

Training and Support

- We provide comprehensive training and support to ensure your staff can effectively utilize and maintain the implemented AI and IoT applications.

- Our team will empower your employees with the necessary skills and knowledge to leverage these technologies for maximum benefit.

- We offer ongoing support to address any issues, updates, or enhancements required post-implementation.

Frequently Asked Questions

Wondering About Something? Let’s Clear Things Up!

We’ve gathered all the important info right here. Explore our FAQs and find the answers you need.

AI & IoT technologies offer numerous benefits for the manufacturing industry. They enable predictive maintenance, enhance quality control, optimize supply chain management, automate processes, improve energy efficiency, enable real-time data analysis, and drive overall operational efficiency.

Yes! We provide custom AI API integration, chatbot development, and predictive analytics for SaaS platforms.

Absolutely! We specialize in AWS, Azure, GCP, hybrid, and on-premises AI & IT integrations.

We follow enterprise-grade security protocols and compliance standards (GDPR, HIPAA, SOC 2).

OUR CLIENTELE

Trusted by Industry Leaders

Real feedback from global enterprises that rely on Nyx for secure, high-performance AI delivery.

Their AI-driven solutions streamlined our business processes by 70%, boosting our operational efficiency.

~ Hanno Van Arde, CEO, Briisk

Nyx Wolves’ AI helped us unlock insights we couldn’t see before, making a game-changing impact on our research.

~ Peter S, Prince William Science Center, Alaska

Nyx Wolves made AI automation simple and effective for us. Their expertise improved efficiency across the board.

~ Mohit Sibal, Bahri

Their AI-driven solutions streamlined our business processes by 70%, boosting our operational efficiency.

~ Hanno Van Arde, CEO, Briisk

Nyx Wolves’ AI helped us unlock insights we couldn’t see before, making a game-changing impact on our research.

~ Peter S, Prince William Science Center, Alaska

Nyx Wolves made AI automation simple and effective for us. Their expertise improved efficiency across the board.

~ Mohit Sibal, Bahri

Their AI-driven solutions streamlined our business processes by 70%, boosting our operational efficiency.

~ Hanno Van Arde, CEO, Briisk

Nyx Wolves’ AI helped us unlock insights we couldn’t see before, making a game-changing impact on our research.

~ Peter S, Prince William Science Center, Alaska

Nyx Wolves made AI automation simple and effective for us. Their expertise improved efficiency across the board.

~ Mohit Sibal, Bahri

Their AI-driven solutions streamlined our business processes by 70%, boosting our operational efficiency.

~ Hanno Van Arde, CEO, Briisk

Nyx Wolves’ AI helped us unlock insights we couldn’t see before, making a game-changing impact on our research.

~ Peter S, Prince William Science Center, Alaska

Nyx Wolves made AI automation simple and effective for us. Their expertise improved efficiency across the board.

~ Mohit Sibal, Bahri

Get a Free Consultation

Ready to revolutionize your manufacturing processes with AI & IoT? Contact us today for a free consultation and discover how our tailored solutions can drive your success.