Table of Contents

Here’s how a Custom Warehouse Management System Helped UPS Handle 2.4M Transactions Weekly

Running a warehouse isn’t glamorous. It’s not all forklifts and walkie-talkies. It’s mostly panic when you can’t find SKU X48Z before the 4 PM dispatch. That’s where we stepped in. UPS needed a warehouse management system that could handle the chaos like scanning, tracking, counting, reporting, delivering and still be flexible enough to actually fit how their warehouses work. So we built them one.

And now? They process 2.4 million+ warehouse transactions every single week without the need to use spreadsheets, duct tape, or daily fire drills. In this blog, you get to know what went behind the scenes.

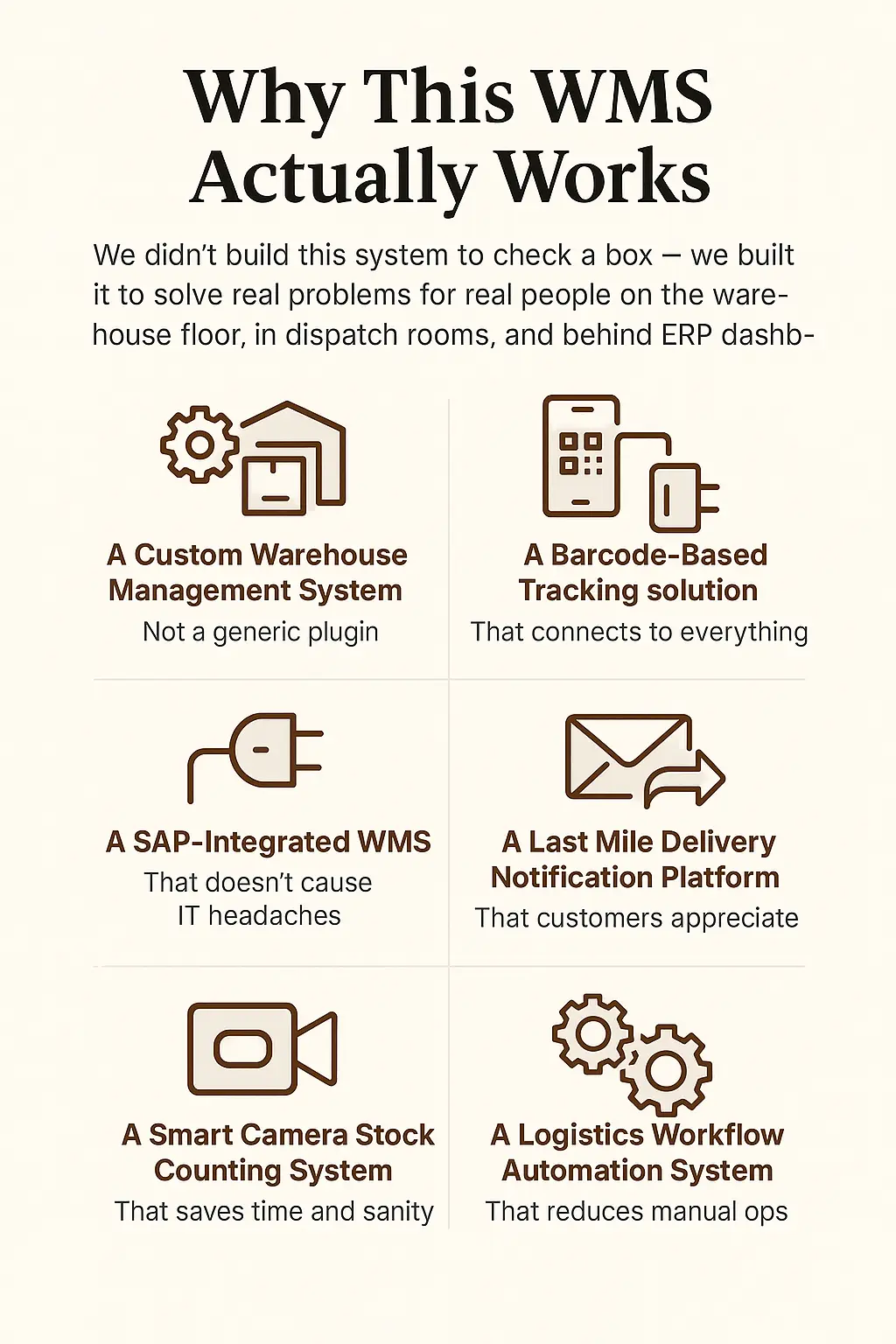

Not Just Another Warehouse Management System

Warehouse Management System is a software solution designed to optimize and automate the day-to-day operations of a warehouse. From inventory tracking and order fulfillment to labor management and real-time reporting, a WMS provides end-to-end visibility and control over warehouse processes.

Most off-the-shelf WMS platforms are like cargo pants from the 2000s, too many pockets in the wrong places. We built a custom warehouse management system that actually fits. Like, tailored-to-your-workflows fits.

Here’s what we packed into it:

- Custom fields (because one-size-fits-none)

- Role-based dashboards

- Barcode-driven inventory tracking that just works

- Mobile WMS for Android and Datalogic devices

- Integration with SAP and Microsoft Dynamics 365

- Support for warehouse fleet and freight tracking

- A built-in last mile delivery notification platform

From Barcode to Doorstep

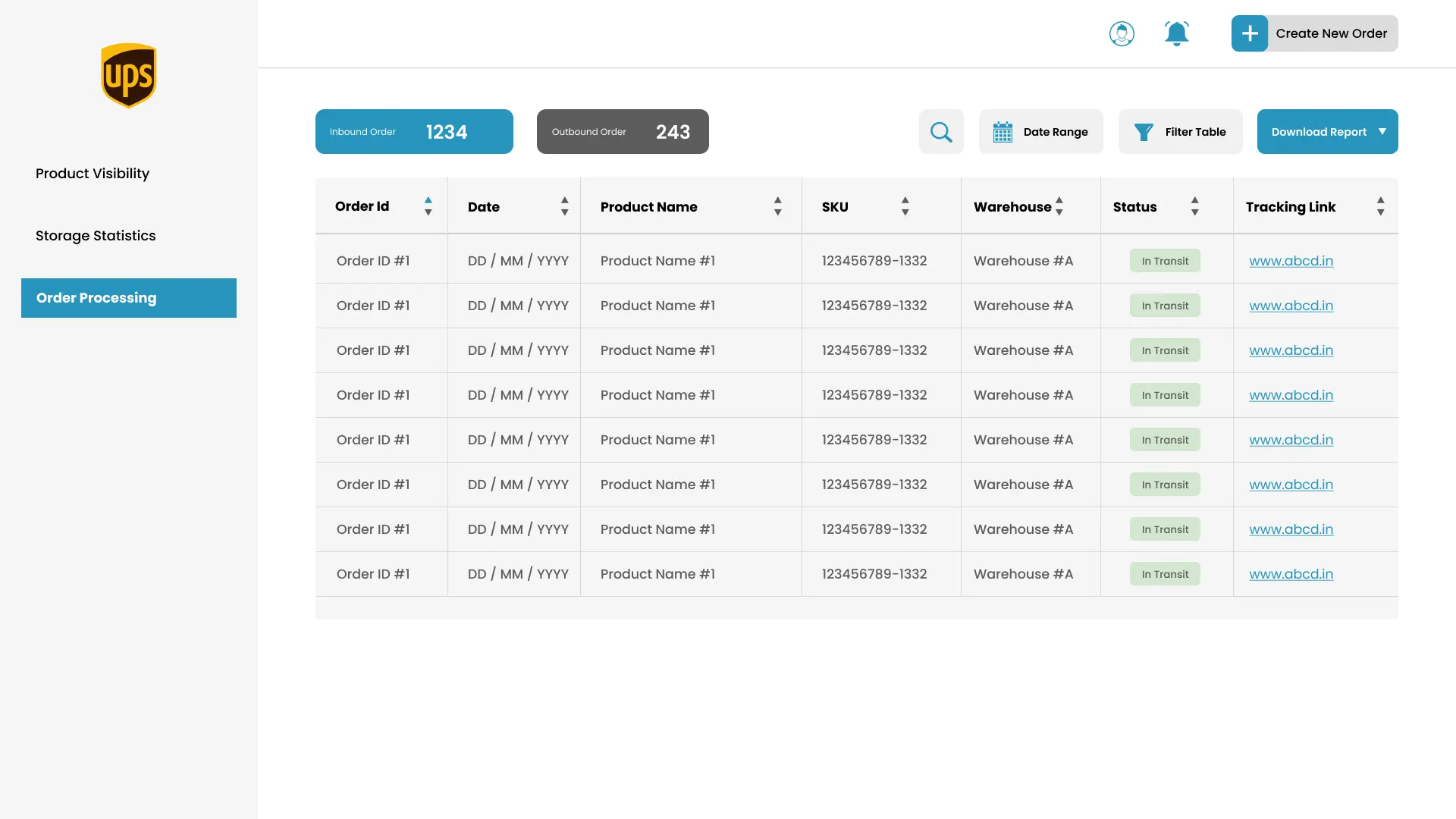

This WMS doesn’t clock out once products hit the loading dock, but it’s in it for the full journey. From the moment stock is received, scanned, and shelved, to the second it lands at the customer’s doorstep, everything is tracked, traced, and synced.

It’s built to connect all stages of the logistics chain not just warehouse shelves, but fleet, freight, and last-mile delivery too. Customers get real-time delivery updates, and internal teams stay aligned across systems like SAP and Microsoft Dynamics 365.

The warehouse manager's job just got way easier:

- Find any product now in any bin, across multiple warehouses instantly.

So tell no to guessing games or radioing three teams to track a lost pallet. - Generate reports without drowning in spreadsheets. Now, everything from stock flow to order history is just a few clicks away. No copy-pasting. No Excel-induced breakdowns.

- Place orders directly to customers with live inventory visibility. You can know what’s available, where it is, and how fast it can ship even before the sales team even asks.

- Track stock movement across warehouses like a control tower, whether the product is being picked, packed, or halfway out the door, it’s all visible in one dashboard.

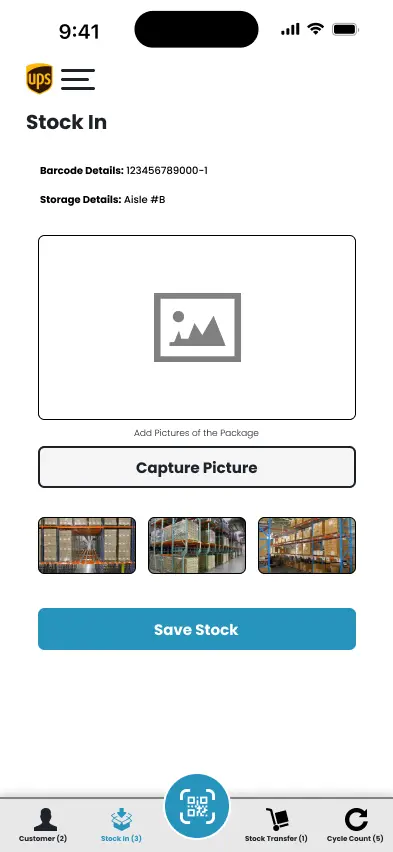

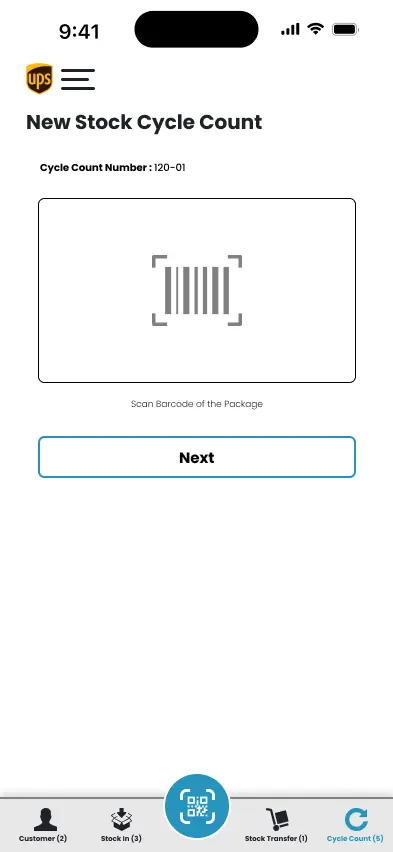

Mobile App Experience: The Warehouse in Your Pocket

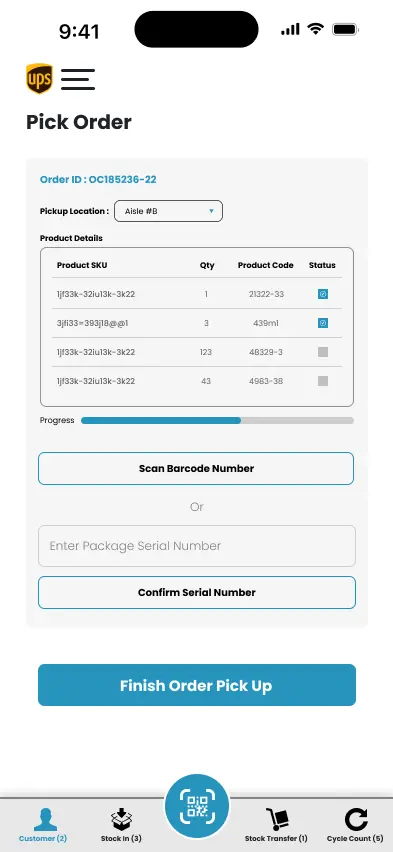

No warehouse manager wants to be stuck behind a desk. That’s why this WMS was built mobile-first. Whether you’re picking orders, scanning packages, logging new stock, or running a quick cycle count, everything can be done from a rugged Android or Datalogic device. Fast, intuitive, and 100% barcode-driven.

Instead of toggling between tabs, forms, and walkie-talkies, teams now handle entire workflows right from the warehouse floor, all synced in real-time to the backend.

Pick orders

Scan SKUs, confirm serials, and pick orders right from the aisle, no paperwork needed.

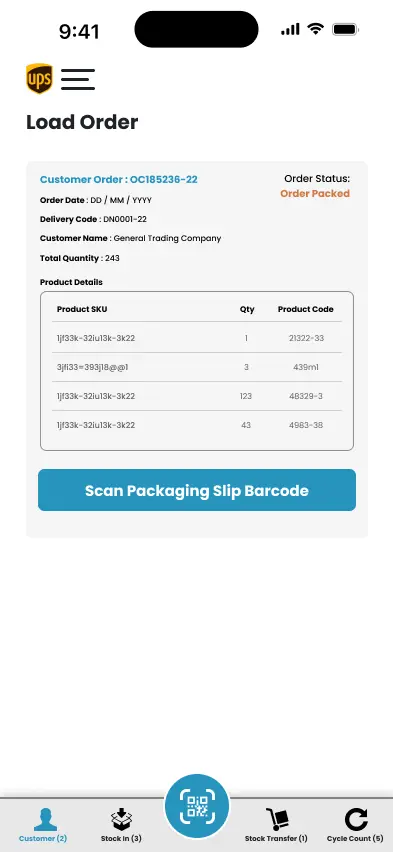

Load Orders

Scan packaging slips and confirm loads before dispatch, smooth and accurate.

Stock in

Log incoming stock with photos, barcodes, and storage details. Everything gets a home.

Cycle Count

Quickly audit inventory by scanning barcodes, no spreadsheets, no stress.

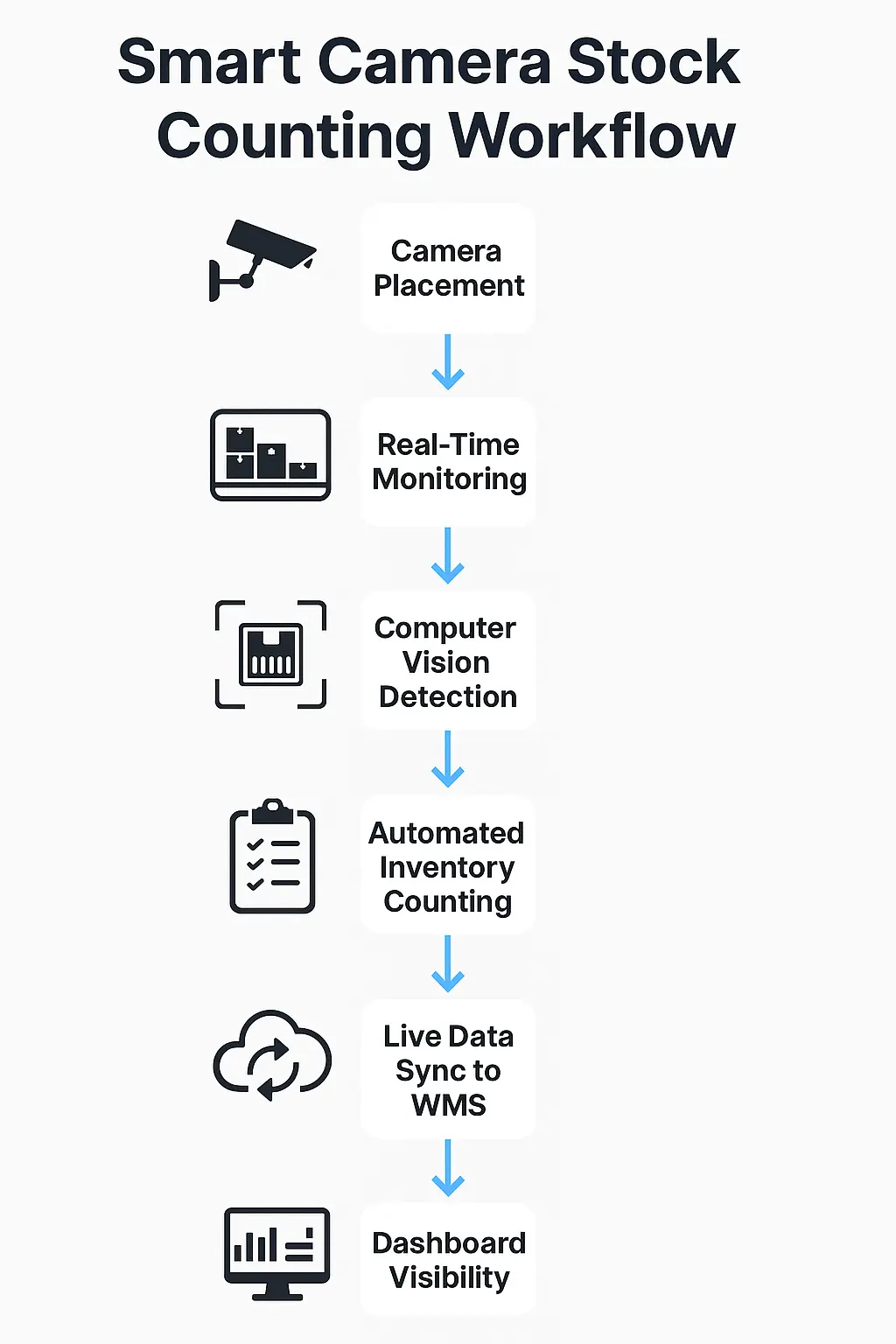

Smart Camera Stock Counting = No More Shelf Scanning Olympics

Manual inventory counting is one of the most time-consuming and repetitive tasks in warehouse operations. Running up and down aisles with a handheld scanner, searching for specific Stock Keeping Units (SKUs), often feels more like a scavenger hunt than a streamlined process. It’s inefficient, physically demanding, and particularly challenging during audit periods when accuracy and speed are critical.

So when UPS wanted a better way to handle stock reconciliation, we gave them exactly that: smart camera-based stock counting.

Here’s how it works:

Cameras are strategically placed to monitor shelf space, pallets, and bin areas. Using computer vision, the system automatically detects product movement and counts inventory in real-time, no manual scanning needed. It’s like having digital eyes across the warehouse that never blink or miss a count.

And because it’s fully integrated into the warehouse management system, the data flows straight into live dashboards and reports. No delays. No missed counts. No weekend-long stocktaking marathons.

Want to see how this works in your warehouse?

- Faster stock audits: What used to take hours now happens passively.

- Improved accuracy: Reduce human error in high-volume operations.

- Happier teams: Because no one enjoys counting boxes row by row.

- Real-time visibility: managers can see discrepancies before they become problems.

Let’s talk about The Impact

- Faster stock audits: What used to take hours now happens passively.

- Improved accuracy: Reduce human error in high-volume operations.

- Happier teams: Because no one enjoys counting boxes row by row.

- Real-time visibility: managers can see discrepancies before they become problems.

Who needs this?

Built for UPS. Perfect for Anyone Who Deals With Stuff.

We did build this warehouse management system for UPS, but it’s not some locked-away, one-time magic trick. This system is designed for any business that touches inventory, logistics, or just needs a break from operational chaos. If you’re nodding along to any of these, you’re exactly who we built this for:

Logistics Teams Buried in Manual Processes

Still using clipboards, Excel sheets, or chasing updates across five platforms? This WMS automates the grind. The barcode scans, stock movement, inbound/outbound logging, so you can finally breathe (and scale).

Ops Managers Tired of Playing ‘Where’s Waldo’ with Inventory

If finding a misplaced pallet feels like a full-time job, you’re not alone. Our system gives you real-time visibility across bins, shelves, and multiple warehouse locations. So, no treasure maps required.

CTOs Trying to Get SAP and WMS

You’ve got SAP. Maybe even Microsoft Dynamics. But they’re siloed, clunky, or allergic to change. We get it. Our WMS speaks fluent ERP, integrates seamlessly, and doesn’t break your stack or your budget.

Anyone This Close to Throwing a Barcode Scanner at a Wall

Whether it’s inconsistent counts, confusing dashboards, or yet another audit surprise, we’ve all been there. This system is designed to bring sanity back to warehouse life, that is intuitive, responsive, and made for humans (not just systems).

FAQs

A custom WMS is built around your exact workflows, team structure, and infrastructure. Unlike off-the-shelf tools that force you to adapt, custom systems like the one we built for UPS offer barcode-driven tracking, mobile integrations, and seamless ERP syncing, all tailored to real-world operations.

Yes, our WMS was fully integrated with both SAP and D365 for UPS. Real-time data sync between ERP and WMS eliminates duplication, delays, and the classic “we’ll get back to you after checking three systems” bottleneck.

The system tracks inventory from the shelf to the customer’s doorstep. It includes last-mile delivery notification features, which means customers receive real-time updates, and ops teams stay fully aligned on delivery status.

Absolutely. The system supports visibility across multiple warehouses, tracks stock movement between locations, and generates consolidated or location-specific reports, ideal for enterprise-scale logistics.